Case Study

Usinage MCP: Leading With Innovation at Heart

Nov 17, 2023

Usinage MCP is a trailblazer in Quebec’s manufacturing industry. The company has been taking on metal fabrication projects of all sizes for customers in industries ranging from medical devices to aerospace. Since the company’s inception in 2002, Usinage MCP’s team has upheld the values of creativity and diversification as they serve each new customer -- a decision that has brought them continued success and a trusted reputation that has only grown stronger over two decades.

The Quebec City-based team’s story begins with Michel Tailleur, a conventional machinist who quickly rose to excellence within his role. Michel was ambitious and driven, and within a few years, he developed a knack for leading teams of manufacturing professionals. Soon, his toolbelt of skills and fiery entrepreneurial spirit led him to open his own manufacturing operation, Usinage MCP.

Leading with innovation at heart

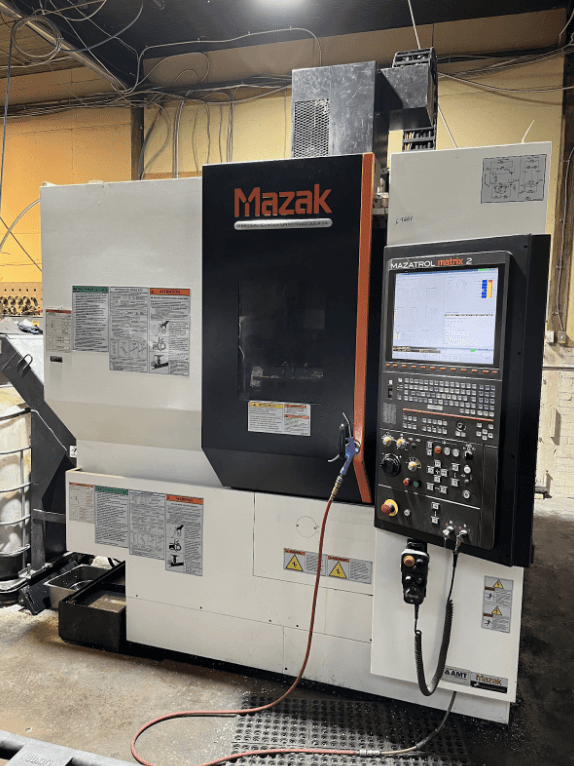

Driven by Michel’s creative spirit and years of manufacturing excellence, it’s no surprise that Usinage MCP’s team has always remained keen on exploring the possibilities that new manufacturing technologies may bring. The company has been a long-time advocate for computer-controlled equipment (CNC) which leverages automation for efficient production and has brought Usinage MCP a competitive edge over manufacturers who have yet to fully explore automation in machining processes.

5 axes Mazak VCU

But this innovative mindset doesn’t just start and stop with Michel -- Michel’s son Gabriel Tailleur joined the team just over a year ago. Equipped with a bachelor's degree in mechanical engineering and a lifetime of experience shadowing expert manufacturers, Gabriel is ready to bring his technical knowledge to the table and work alongside his father to make Usinage MCP as future-proof and innovative as ever.

A competitive edge for the automated age

Whether it’s adding new perspectives to the team, or exploring new technologies, Usinage MCP always has its finger on the pulse of the industry and is ready to act with the best interests of their customers in mind. The team has recently acquired state-of-the-art 5-axis vertical machining centers to take on even more complex machining jobs in record time.

In fact, Michel, Gabriel and the entire Usinage MCP team have recently made automation a company priority. Having continuously seen the positive impacts of being an early adopter of cutting-edge technologies, the team is currently working on a project to embrace automation’s full potential to stay resilient no matter what the future of manufacturing may hold.

Serving trusted Canadian companies

As many Canadian businesses remain in the dark when it comes to understanding what the future holds, it is more essential than ever for teams to create networks of resilient business partners ready to brace for the challenges that economic changes, geopolitical events or natural disasters may present.

With this in mind, Usinage MCP has made it its mission to support Quebecois and Canadian businesses by leveraging the power of innovation and helping Canada shine on the global stage as a leader in manufacturing automation.

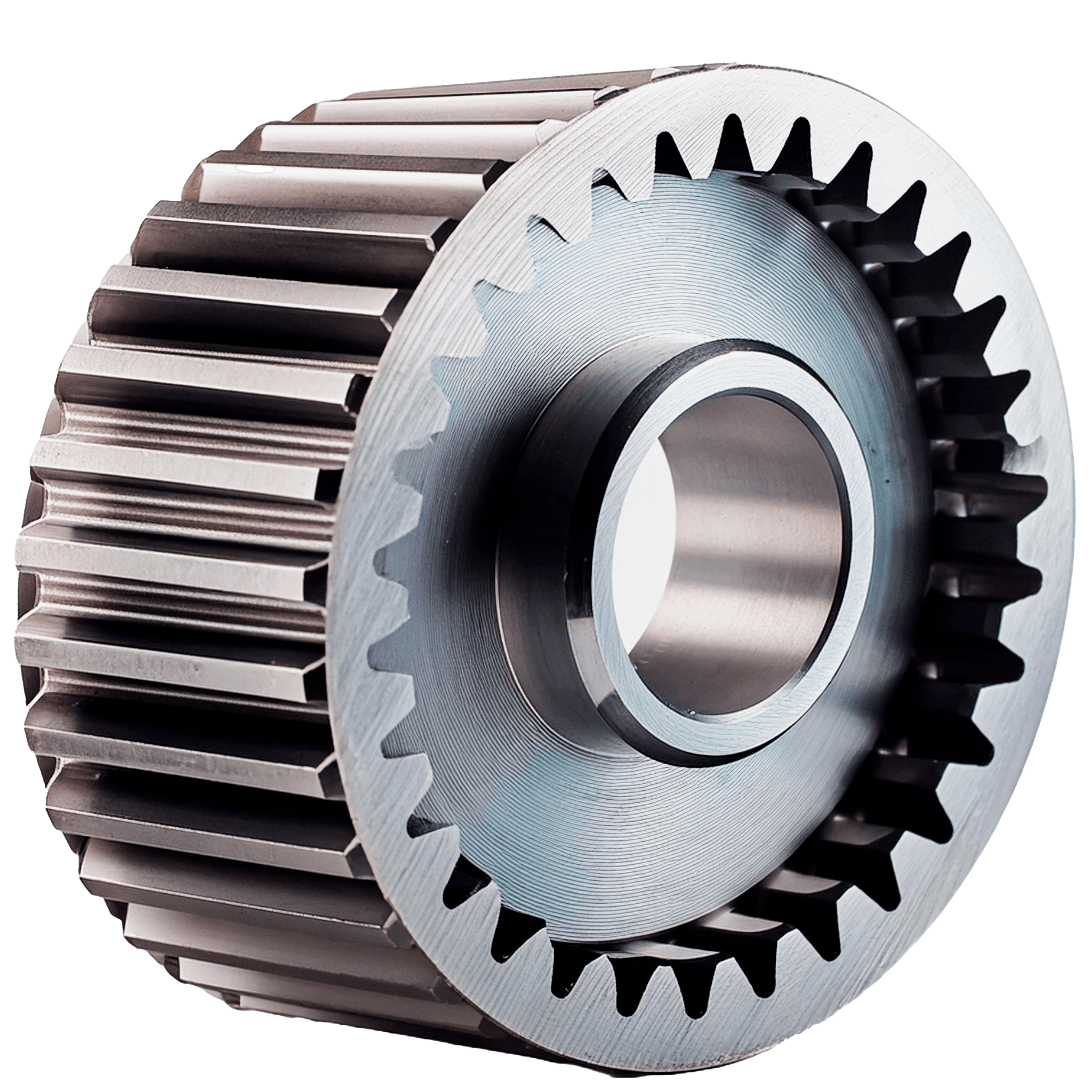

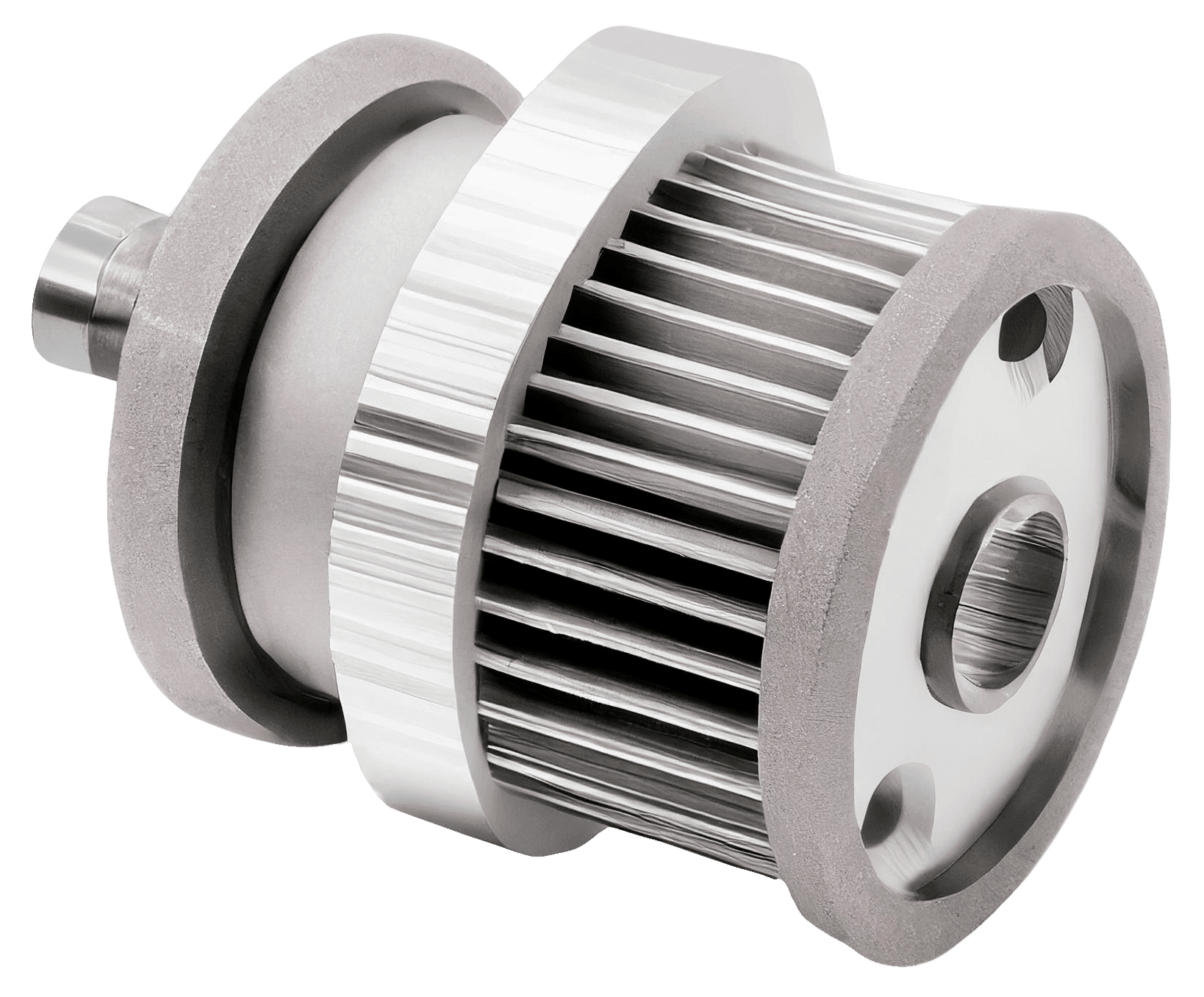

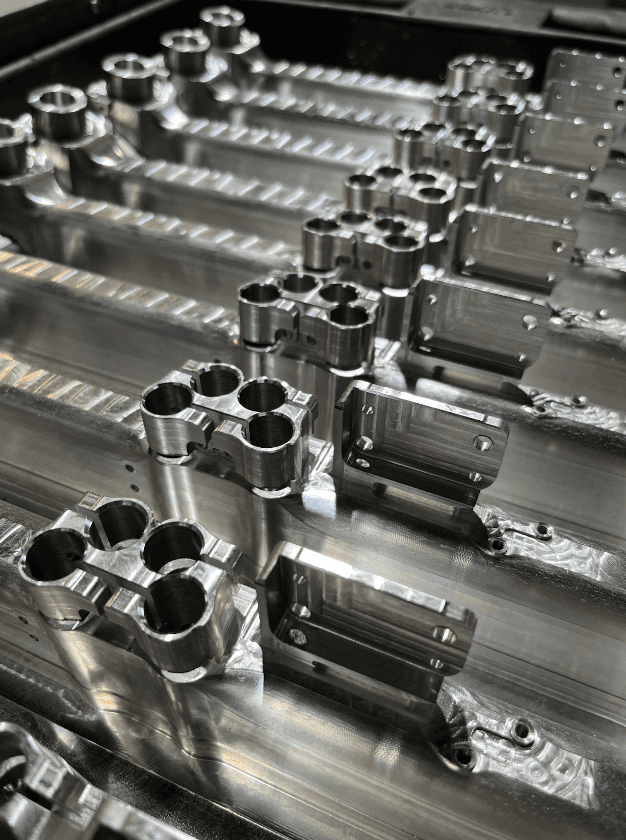

Example of project they specialize in

Through the Axya platform, Usinage MCP has not only managed to uphold this mission by serving emerging Canadian companies, but has also further cemented its reputation as an excellent partner ready to take on challenges of all sizes. Usinage MCP’s years of experience with CNC machining have made them an expert in the fabrication of complex CNC parts and a go-to supplier for many buyers on Axya with diverse needs.

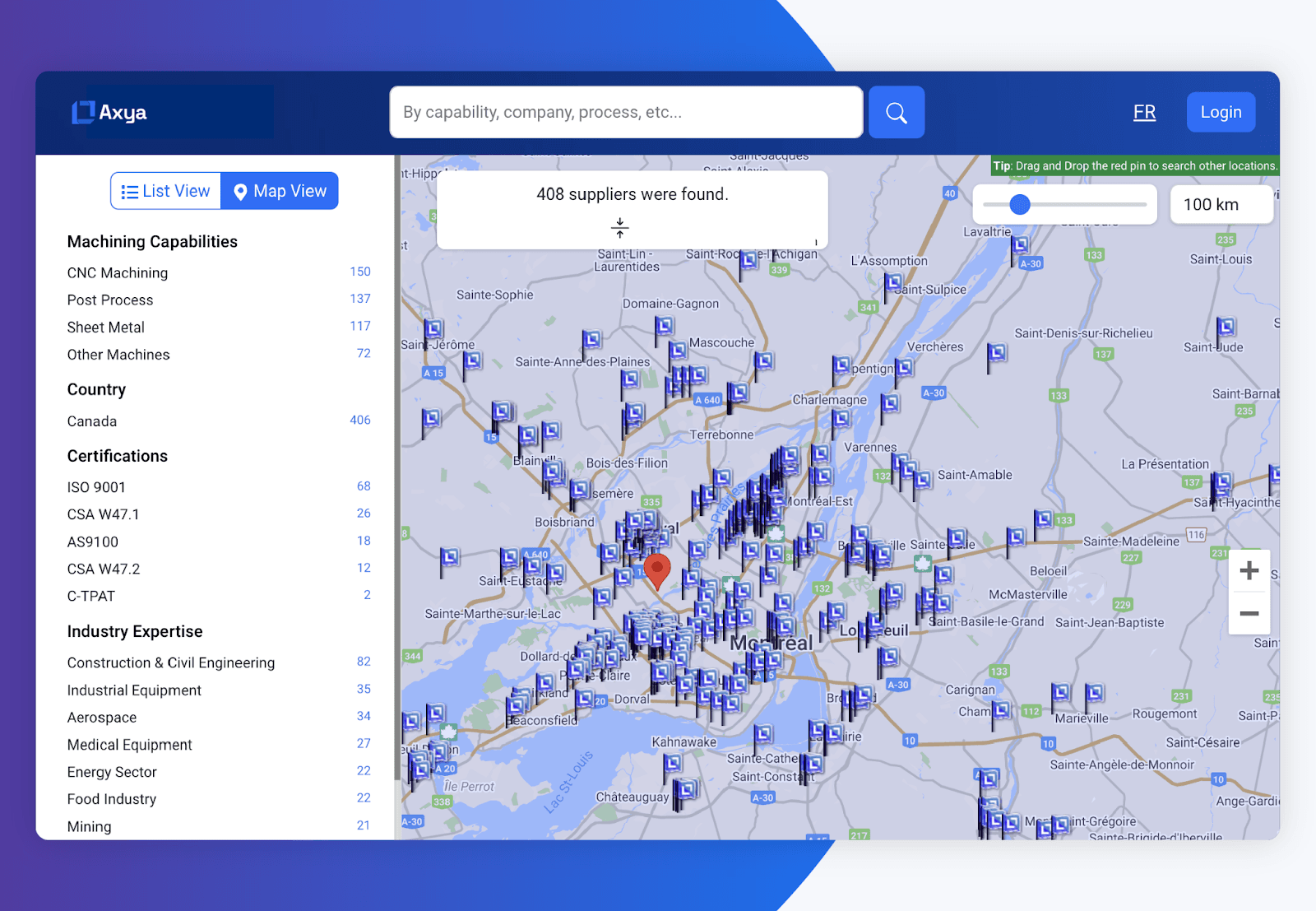

Gabriel and Michel can be easily found through our free supplier directory tool to find capable manufacturers (Register here)

Furthermore, the company’s extensive experience with a variety of industries has made them a trusted manufacturer for large aerospace clients and SMEs across various fields. With a growing team of manufacturing experts on their side, the team possesses the skills and equipment necessary to tackle all aspects of a complex project-- from design, to the finished part and every step in between. Axya buyers have also noted Usinage MCP’s fast turnaround times and personal customer service as added bonuses to an already top-of-the-line manufacturer experience.

Our Head of Customer Success, Alexandre Laliberté had this to say about their operations:

What is impressive in this company is their awareness of their competitive advantage and the focus they have on submitting offers on the jobs they know they have an edge: CNC Machining of small to medium size volumes with medium to high level of complexity in aluminium, stainless or plastic that requires fast turnaround time and competitive pricing.

This strategy - coupled with a fast, reliable and dedicated customer facing team - allowed them to be very successful in developing new lasting relationships.

Just through Axya, they were able to prove themselves worthy of being added to more than 5 Approved Supplier Lists of customers ranging from large aerospace tooling departments down to smaller SMEs in the automation industry.

The team’s creative drive, willingness to embrace innovation and dedication to serving Canadians have made Usinage MCP an excellent business partner-- one that Axya buyers they know can count on and grow with for years to come.

To learn more about Usinage MCP, do check out their website