Case Study

Brouwer Kesmac & JVC Precision: Finding Synergy Through the Pursuit of Innovation.

Jul 14, 2022

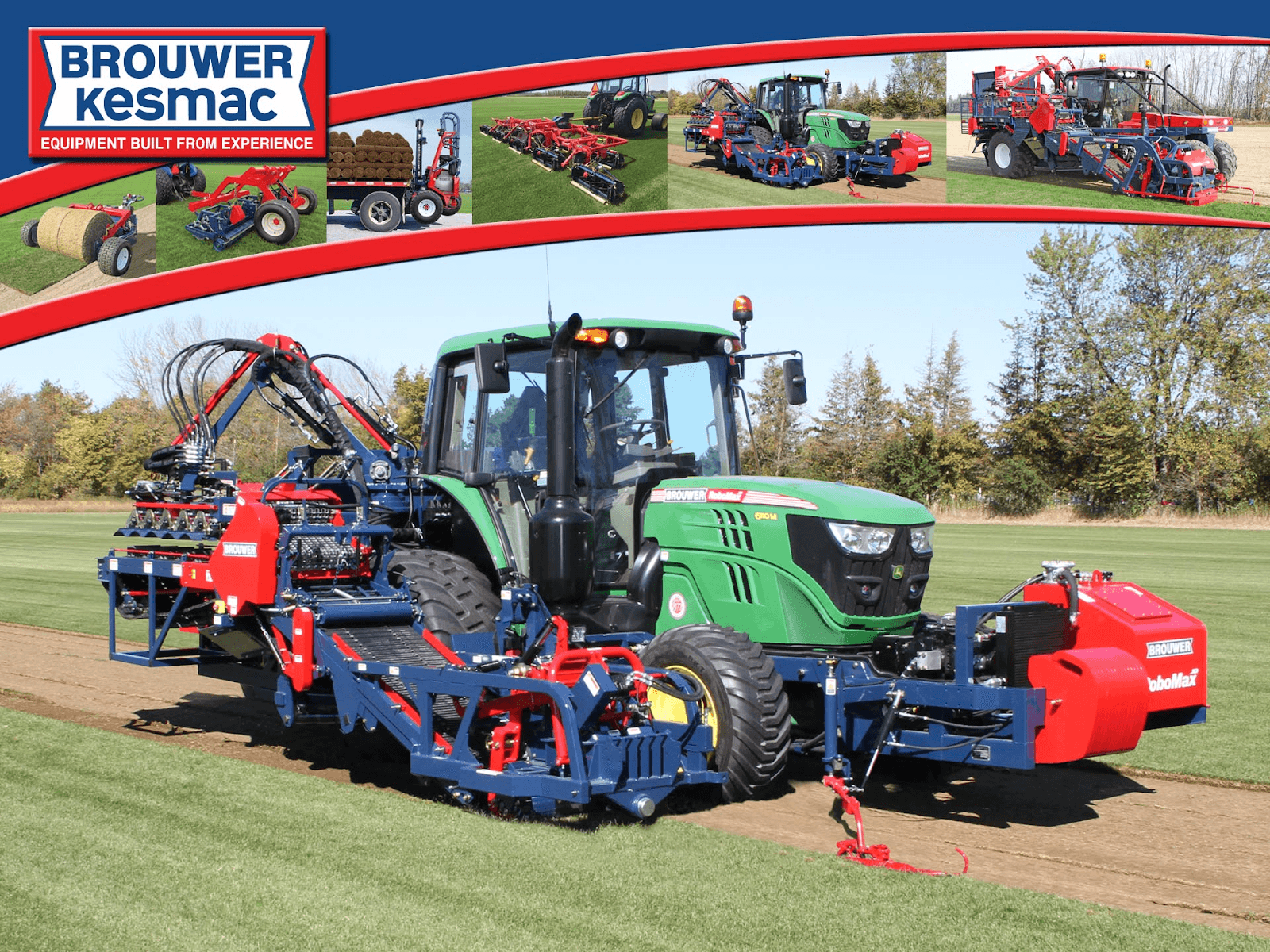

When many Canadians think of innovation and quality within the agricultural industry, they think of Brouwer Kesmac. The Kewsick-based manufacturer of various lines of turf equipment has served numerous agricultural sites looking to get their hands on the most cutting-edge technologies available for harvesting sod-- a resource integral to countless companies and individuals across the globe. Founded by father-son duo, Gerry and Eric Brouwer, the company recently celebrated their 50th anniversary in 2022 and marked half a century of commitment to efficiency and reliability in agricultural machining.

A lasting legacy

Despite their long-standing legacy as a trusted industry name, Brouwer Kesmac continues to push the limits of agricultural machining and explore new methods that embrace innovative technologies. In fact, the company credits their 'history of innovation' as a large part of their ability to maintain a strong reputation and cultivate a global network of customers over the span of five decades. The team, which first began manufacturing equipment out of the family sod farm, cites several pivotal points wherein they researched, tested and incorporated new technologies into their equipment, and subsequently, enabled experts worldwide to harvest sod more efficiently. From creating one of the first truck-mounted forklifts on the market to developing rotary and reel mowers for the industry's growing needs, Brouwer Kesmac has always kept the rapidly-changing needs of customers at the forefront.

Keeping innovation at heart

The company continues to operate with this innovative approach at heart. Paired with its continued operations as a family-run business, Brouwer Kesmac manufactures several lines of agricultural products-- harvesters, sprayers, sod cutters and more. Recently, the company has turned a significant part of its innovative focus to the possibilities within automation -- a feat that many manufacturers are striving to explore in order to help customers adjust to an increasingly fast-paced and remote society. Having launched their first automatic sod harvesters -- the Robomax JD and 4000-R-- just two years ago, the company now looks to expand their automated offerings and help even more customers cut costs and save time harvesting.

With many equipment options and even more technologies in the works, the Brouwer Kesmac team is constantly on the lookout for experienced suppliers to rely on for new product launches and day-to-day production. With team members playing several roles within the company, the family-run business highly values creating a trusted network of local partners whom they can rely on in emergencies, periods of innovation and all times in between.

Despite having a tried-and-true process in place for managing their metal part RFQs, the Brouwer Kesmac team sought out ways to work with new local suppliers -- especially those which shared an appreciation for innovation and had cutting-edge machining capabilities in place. Curious to see what the local industry had to offer, they joined the Axya platform and uploaded an RFQ for one of their welded assembly jobs. Within a few days, the team's requests were securely uploaded, and they began receiving numerous quotes from suppliers across Ontario and Quebec.

Finding a modern-day match

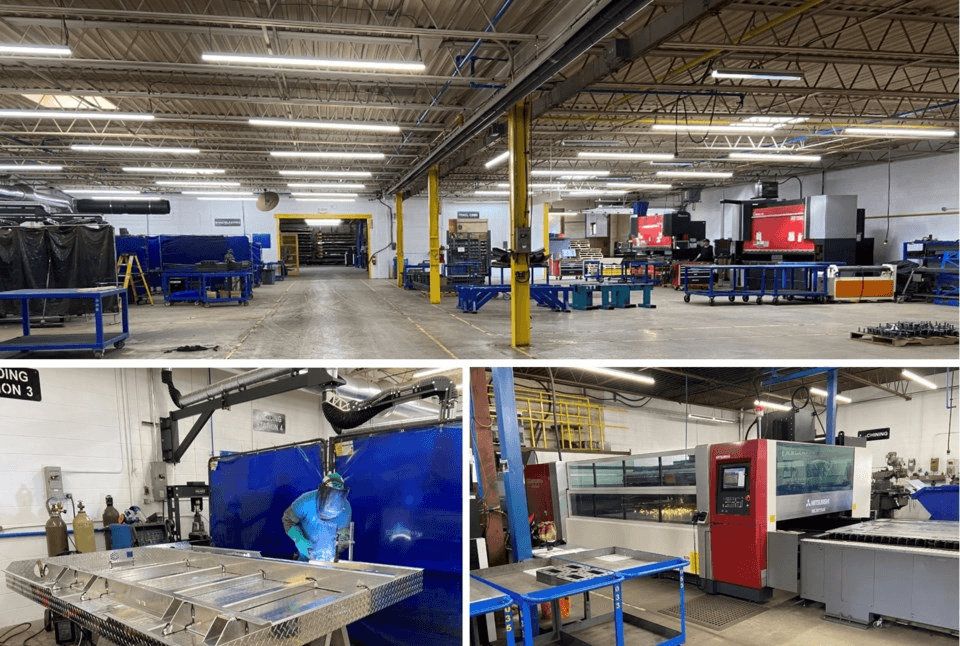

In Oro-Medonte, Ontario, a township located only 90km away from Keswick, JVC Precision prides itself as a machine shop with a wide range of manufacturing design and fabrication capabilities. The team possesses nearly 17 years of experience in serving customers nationwide in a variety of industries. The shop uses a collaborative and iterative approach to tackling projects to ensure maximum customer satisfaction.

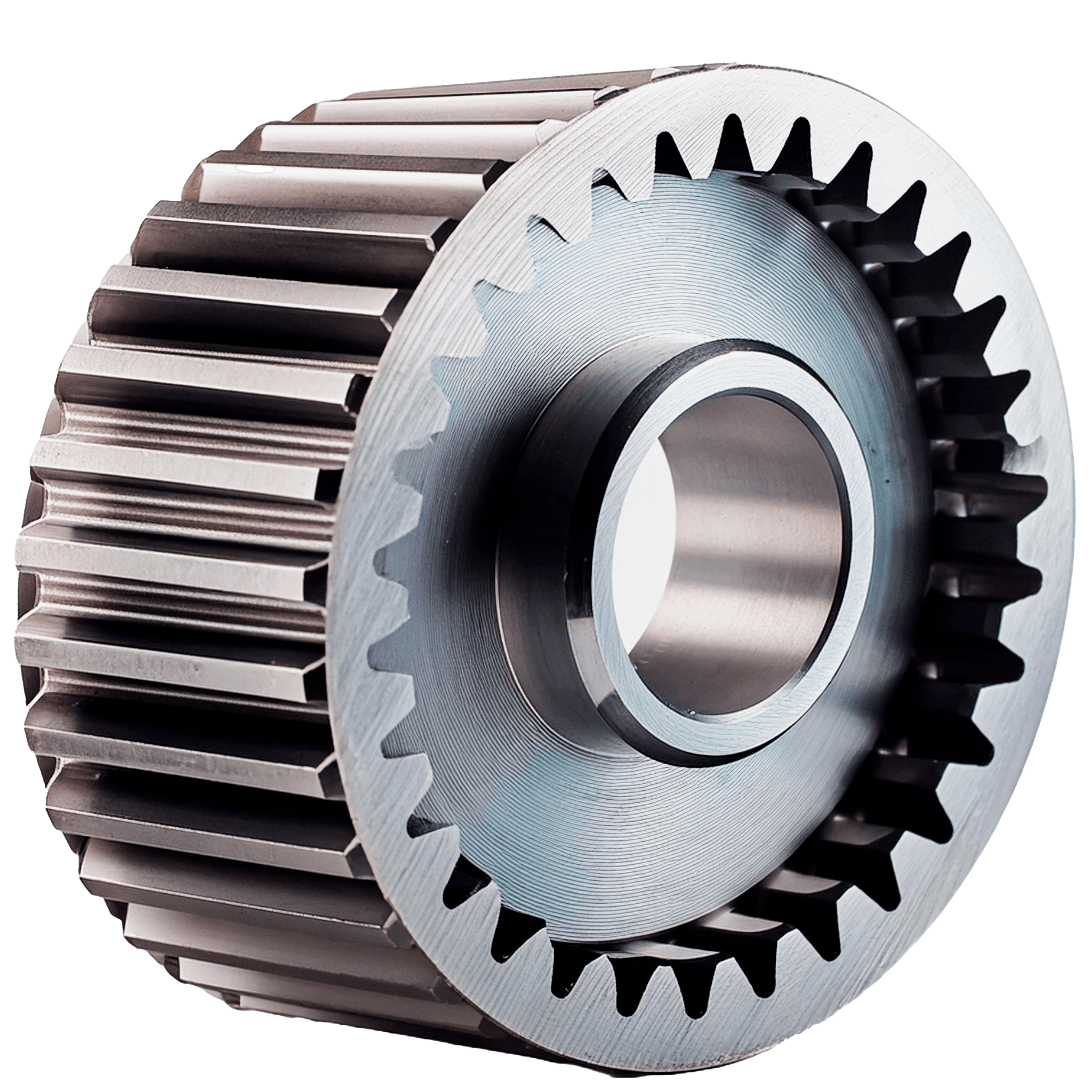

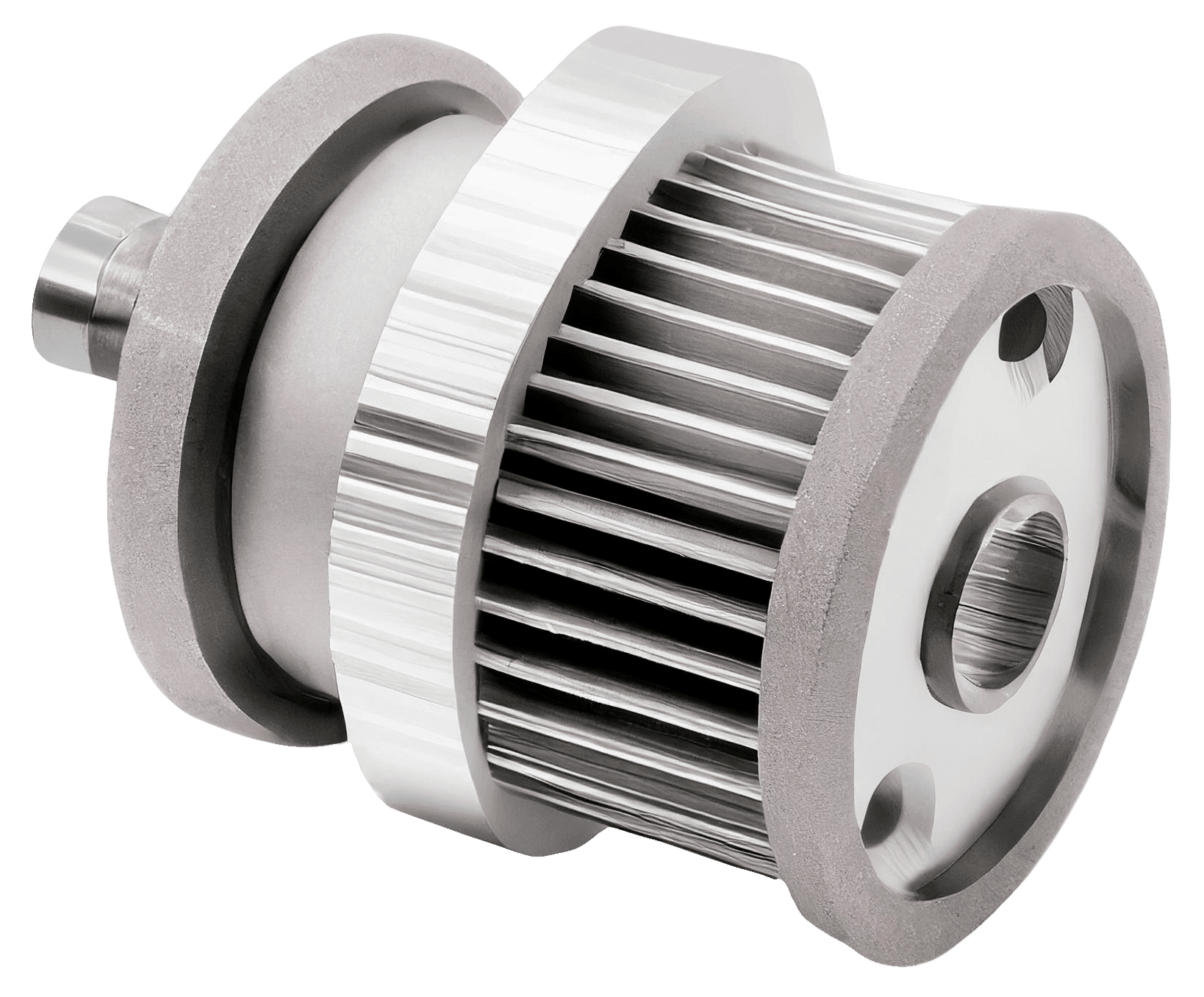

Moreover, the shop is home to some of the most novel machining technologies on the market. Alongside capabilities in welding, assembly, and more, JVC Precision possesses state-of-the-art CNC machines equipped with fiber lasers, automatic pallet changers and vacuum-lifting cranes-- all integral technologies that enable the shop to create higher-quality work and set themselves apart from others.

Upon seeing JVC Precision's bid, Brouwer Kesmac found abundant potential in the shop's close proximity to their headquarters, their passion for collaborative manufacturing relationships and a shared understanding of the value of innovation. An added bonus? JVC Precision-- now a premier employer in the Orillia area-- also had its beginnings as none other than a father-son team.

With all these factors in mind, in addition to price, the shop was selected to contract with Brouwer Kesmac-- a deal that marked the first opportunity for both parties on the Axya platform. Despite their need to manufacture multiple recurring metal parts, Brouwer Kesmac found JVC Precision to be an ideal fit for their challenge and continues to rely on the shop for various custom fabrication needs. Within less than 2 weeks of uploading their first RFQ, Brouwer Kesmac was able to find a new supplier and save countless hours in the search process– all while working locally via Axya.

To learn more about Brouwer Kesmac or JVC Precision, visit their websites.