Case Study

Robsol Robotic Solutions: Automation and Innovation at All Levels

Sep 29, 2023

Robsol Robotic Solutions is focused on using innovative robotic technologies to meet ever-evolving industry demands. The company offers a range of robotic solutions that enable customers in a variety of industries to leverage the advantages of automation in their production processes.

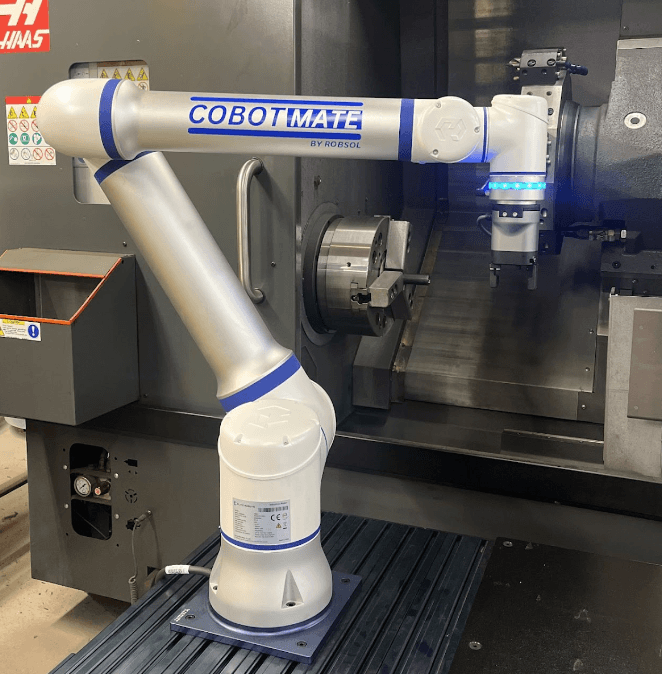

COBOTMATE the collaborative production robot by RobSol

Robsol’s state-of-the-art technologies have helped clients dive head-first into the world of automation-- an often challenging undertaking for companies built upon traditional or manual production. The Robsol team possesses experience in both hardware and software-- a combination that effectively equips them with the ability to adapt to any potential client’s needs. Whether it’s a manufacturer with a fully automated production process, or a packaging client hesitant to explore new technologies, Robsol brings their custom, consultative approach to each new project and finds room for each new client to streamline their production landscape.

The team specializes in robotic solutions for palletizing and depalletizing, welding, handling and more. Along with their expertise in the design and integration of these technologies, Robsol has created their own line of robotic palletizers, the RS-10 and RS-10C. These machines enable manufacturing and packaging professionals to increase efficiency thanks to easy integration with their existing production lines, industrial-grade production, and integration with palletizing software.

You can check out RobSol cobot welding solution in this video!

Driving Innovation from the Top

Robsol is proudly led by automation experts and industry veterans Jean Dion and Sofiane Nekkah. The two forward-looking leaders bring decades of combined experience in industrial manufacturing and complex robotic solutions to the team. Jean comes from a background in food packaging-- having previously worked for companies such as American Can, Sidel, and Geosaf where he specialized in the manufacture of conveyors, bottling equipment, and high-performance machines for canning and packaging. His colleague Sofiane is a mechanical engineer by trade who possesses over 12 years of experience in complex robotic solutions.

Axya is glad to be working with Sofiane, Jean and the RobSol team!

With these two in charge, it is clear how Robsol has managed to make itself a trusted source of automation authority. The two have led their team to become experts in design, programming, tooling and more. Above all, the duo places a high emphasis on customer service and relationship building-- citing the importance of exceptional listening and adapting to a client’s needs in such a diverse sector.

Embracing Industry 4.0+

The Laval-based team’s enthusiasm for the possibilities of Industry 4.0+ and the synergies between man and machine is yet another factor that has drawn numerous clients to Robsol. The team helps clients develop advanced manufacturing networks featuring machines that possess the real-time capability to analyze production insights and make adjustments. With these invaluable processes in place, clients are able to adapt to increase production efficiency and reduce risk easily.

Over the last few years, many Quebec-based companies in the manufacturing sphere have been faced with a labour shortage. Despite there being many job vacancies, teams have found it difficult to absorb talent from the local manufacturing market. With Robsol’s help, manufacturing companies have been able to continue to increase their production capacity as they fill said vacancies by exploring the possibilities of increasingly connected machining networks, all while providing current and potential employees with specialized skills in robotization and collaborative industrial production.

You can check out the full interview with Sofiane Nekkah on how they are tackling this challenge in an ingenious way

New tools for unleashing efficiency

As a part of Robsol’s culture of innovation, the team leverages Axya to digitize, optimize and automate their engineering team’s procurement processes.

To provide their clients with highly customized solutions, Robsol’s procurement process involves purchasing specialized parts on a regular basis-- a process that previously involved filing through supplier lists, sending out packages for each custom part, answering supplier questions by email and vetting numerous quotes. This process not only involved hours of tedious work for the engineering team but was also susceptible to the risk of important supplier emails falling through the cracks or other errors involved in manual processes.

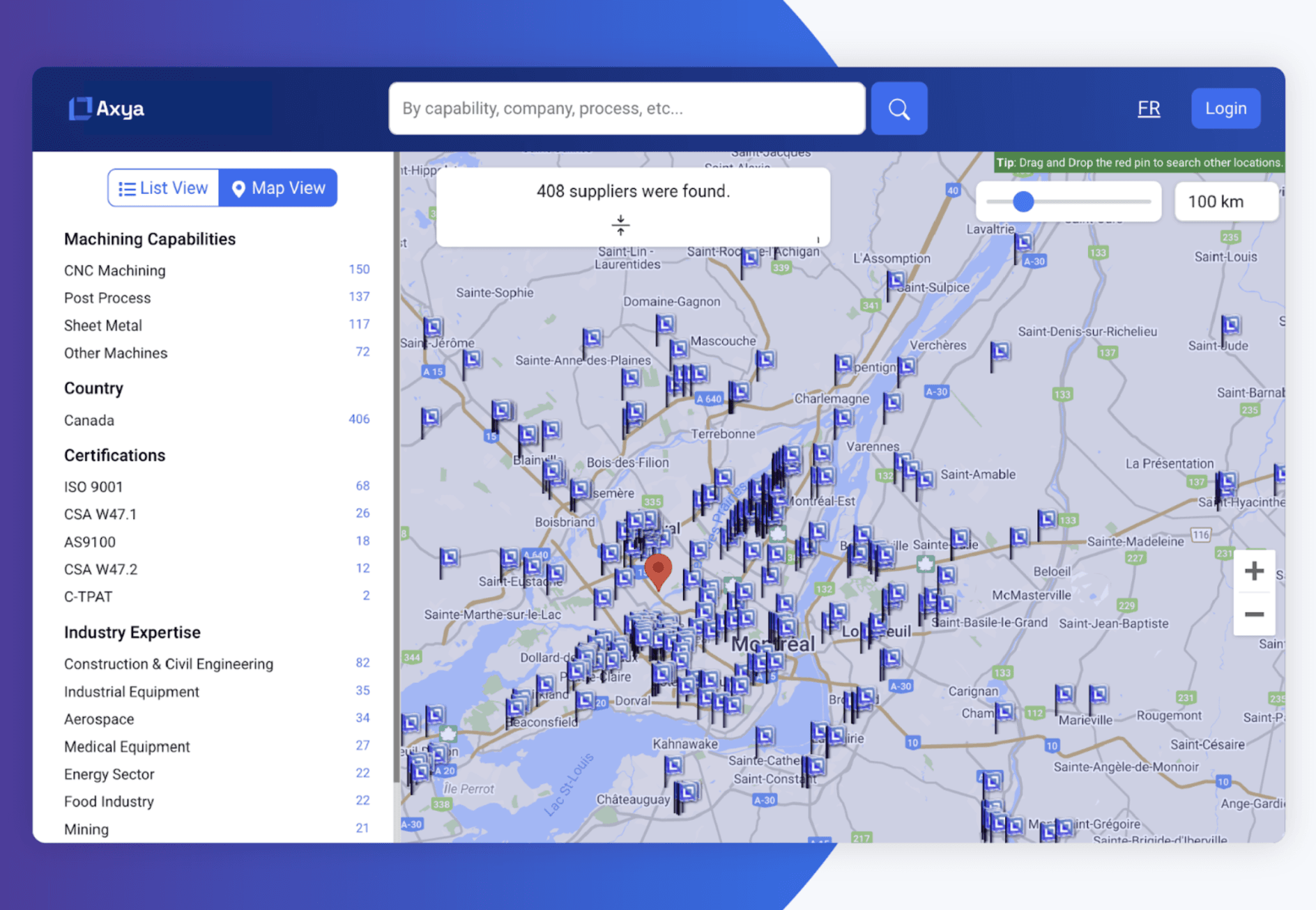

Through Axya, the team now easily uploads BOMs and sends out their structured package for quotes to a wide network of suppliers in just a few minutes. Moreover, Robsol is able to consistently develop new supplier relationships through Axya’s supplier network and find manufacturers capable of taking on ad-hoc projects with short turnaround times.

It is very easy to find new suppliers with the right capability thanks to the interactive map

The platform has also allowed the team to better structure their supplier database and gain visibility into ongoing and past purchases-- key information which allows the company to reflect on the strengths of their business partners and work further with their suppliers of choice in the future.

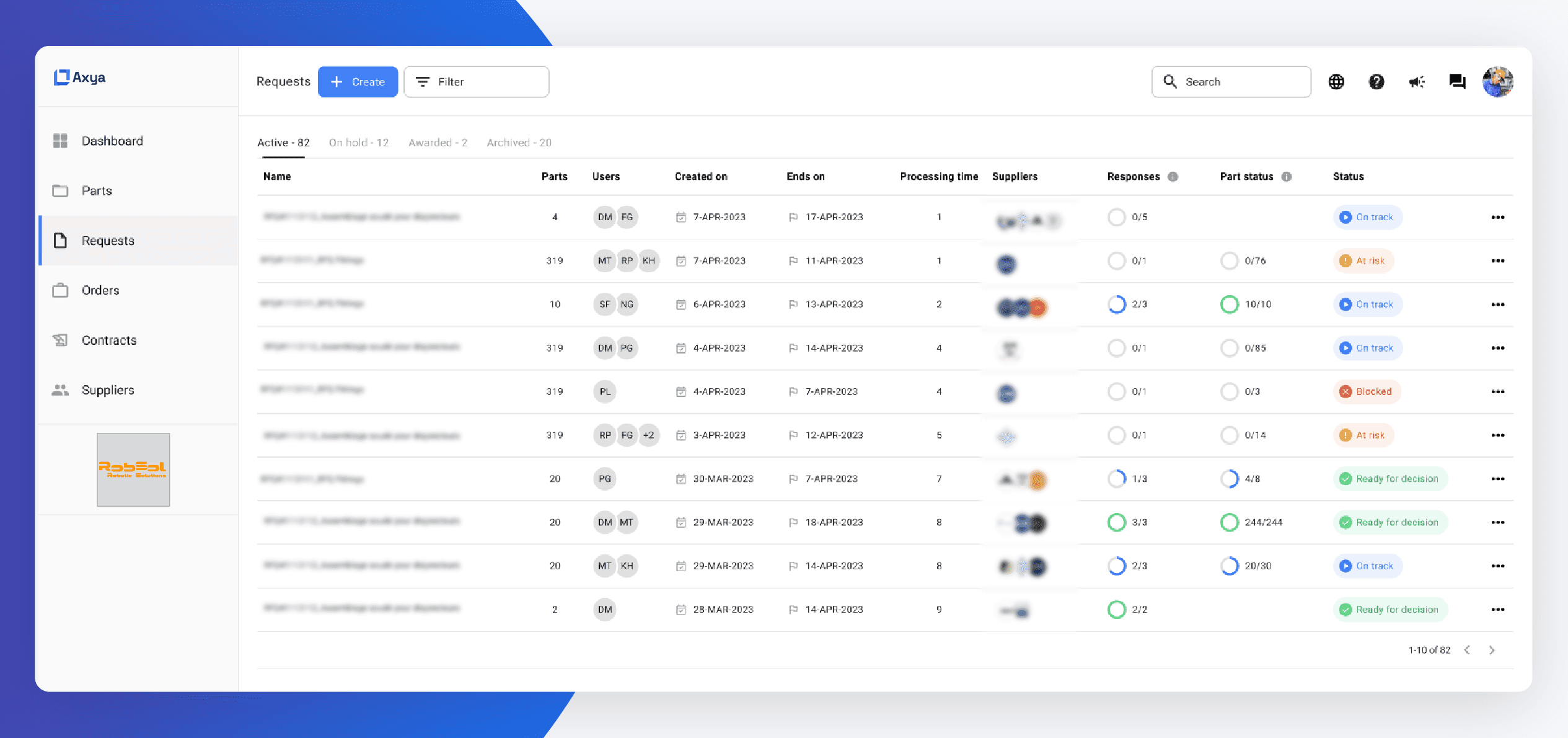

RFQ Module, allowing procurement professional to follow their procurement activity easily

Robsol stands as a shining example of a company embracing automation throughout all facets of their operations. However, the team has only just begun on its journey of exploring all that innovation has to offer. Robsol plans on keeping their eyes peeled and minds open to new solutions to best serve their clients for years to come.

To explore RobSol solutions, head to their website: https://www.robsol.io/