Case Study

OSI Machinerie : Innovation from the Shop Floor to the Supply Chain

Jul 11, 2023

Canada is one of the world’s largest producers and exporters of lumber, and its wood product industry is crucial to businesses both locally and internationally. In 2020, Canada’s industry was valued at just over $635 billion-- making up 6% of the country’s GDP. As a global leader in streamlined wood product manufacturing, it’s now more important than ever for Canadian businesses to pivot accordingly and keep up with the changing demands.

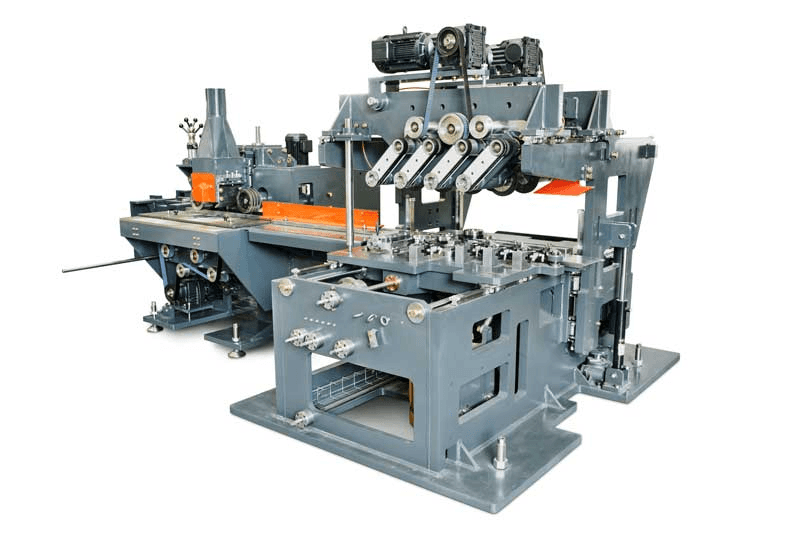

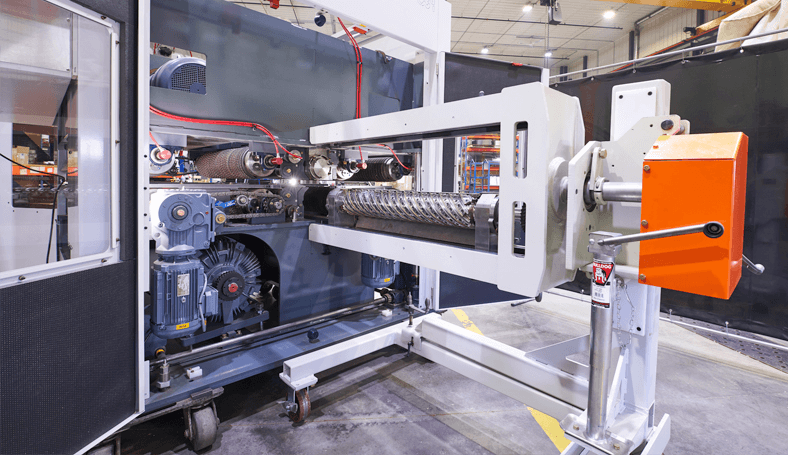

Behind these pivots towards new technologies are companies like OSI Machinerie in Saint-Georges, Quebec. For nearly 36 years, OSI Machinerie has been an industry leader in Quebec’s wood processing equipment space providing products such as sanders, planers, matchers, sorters and more to companies worldwide. From furniture to wood floors and mouldings, OSI’s equipment plays an integral role in manufacturing the products that we use in our daily lives.

Side-Matcher SM-450

The team’s process for creating a product involves creative design and engineering, an iterative development approach, and multiple tests to ensure that the equipment meets industry standards.

On top of its innovative solutions and a tried-and-true process for product manufacturing, the company also attributes a large part of its competitive edge to its unmatched after-sales service and team of technicians who ensure that customers are supported as they interact with the company’s machines for years to come.

Equipment you can trust

The wood processing industry has undergone significant changes over the years since OSI Machinerie started its operations in 1987. The advent of computerization and automation has made it possible for companies to achieve precise results and enhance production efficiency using the appropriate equipment. Despite these changes, OSI Machinerie has maintained its reputation for providing top-notch industrial equipment and innovative technologies to wood processing teams.

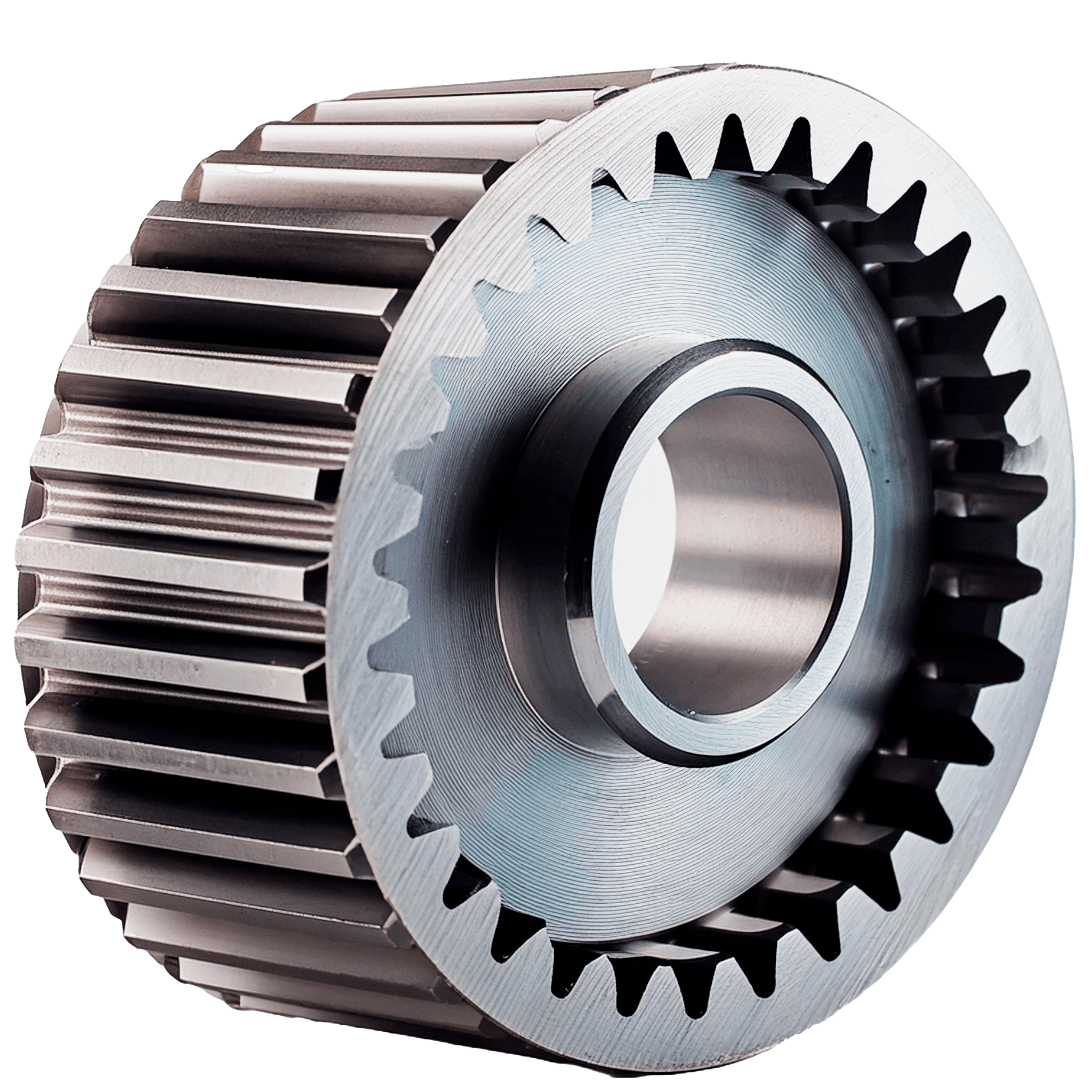

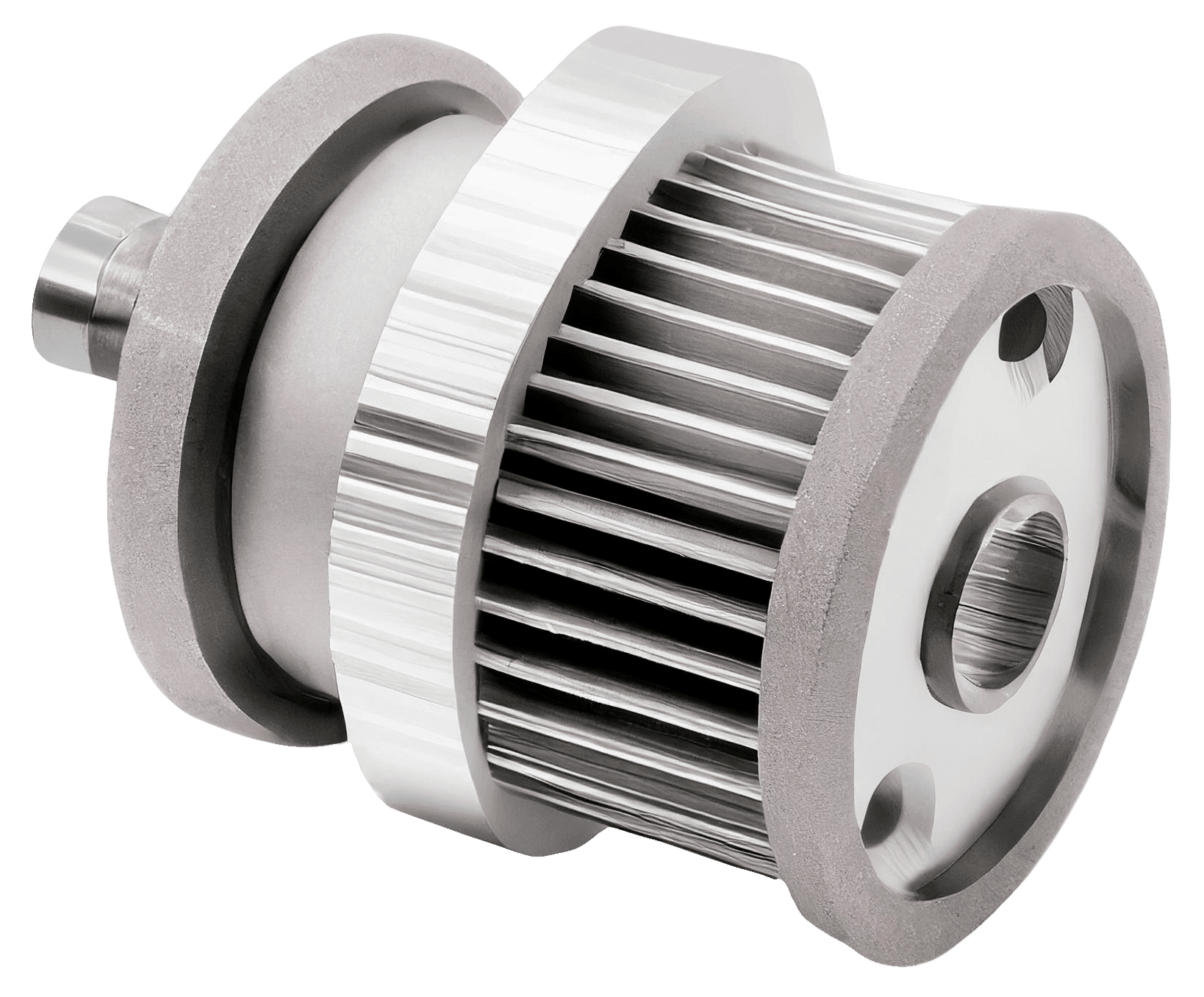

Take OSI Machinerie’s most popular products as an example -- its Self-Centering Planers (SCP). Used to manufacture products such as flooring, doors, and cabinets, the SCP enables manufacturers to make optimal use of every single board-- despite defects such as twists or splits. With options for both North American and European wood product manufacturers, the SCP’s patented technology saves on the amount of wood wasted in the production process and cuts down on cost and time in the process.

SCP serie

Unleashing efficiency

Innovating for efficiency is no foreign concept for the team at OSI Machinerie-- it’s what the company itself has been helping wood product manufacturers do for years. The team’s machines help companies with varying levels of automation expertise and further guide them towards a more precise, cost-efficient and sustainable manufacturing process.

OSI Machinerie’s pursuit to help its customers with innovation is also reflected within the company’s own internal mission. The team had been searching for a tool that could help streamline their procurement process-- one which involves the company’s buyers monitoring several streams of communication for various projects and ensuring valuable data on suppliers is properly tracked for improvement in future projects.

The OSI Machinerie team soon tried managing their supplier relationships with Axya, and within a few weeks, the team had found their ideal platform for organizing knowledge on their suppliers.

Axya’s deployment started on their sheet metal fabricated parts category, which included a handful of suppliers and a single type of requests. After just 3 weeks, the workflow was well established and well adopted by their buyer. The usage was subsequently to all fabricated parts.

After only 2 months, Axya was fully integrated within 100% of their requests. From engagement to fabrication specialties, they could now better target appropriate suppliers for each new project.

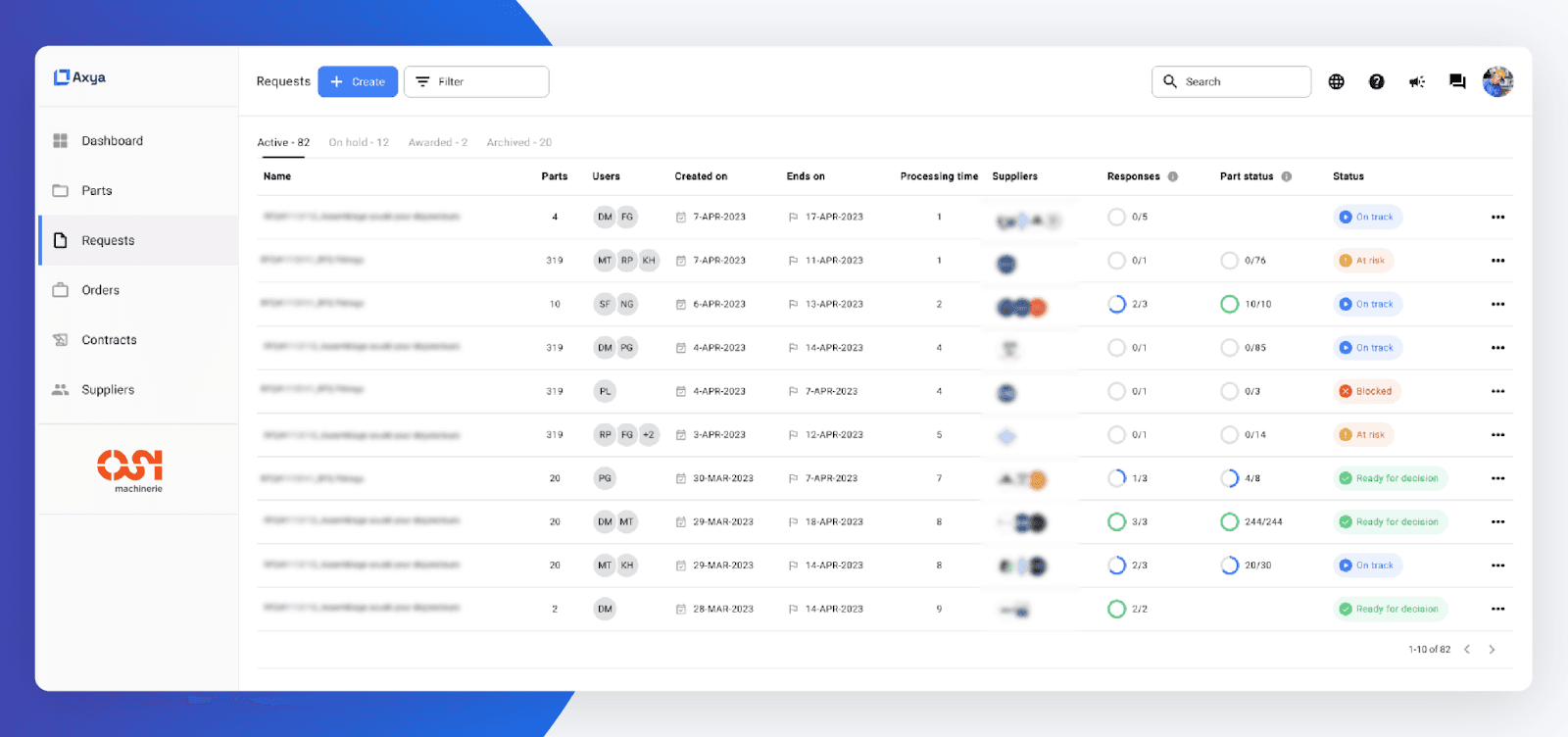

Picture:

Strategic Sourcing Module, allowing procurement professional to follow their procurement activity

The team found further success with Axya’s ability to track supplier relations and monitor a project’s progression with real-time dashboards. A single buyer is now able to manage up to 50 RFQs and more than 100 quotes per month coming from up to 50 different suppliers - while operating other strategic tasks!

On top of this, OSI was able to save valuable time (+60% gain in efficiency) previously wasted in the error-prone manual entry process by synchronizing procurement data to their ERP and generating reports on ongoing activity.

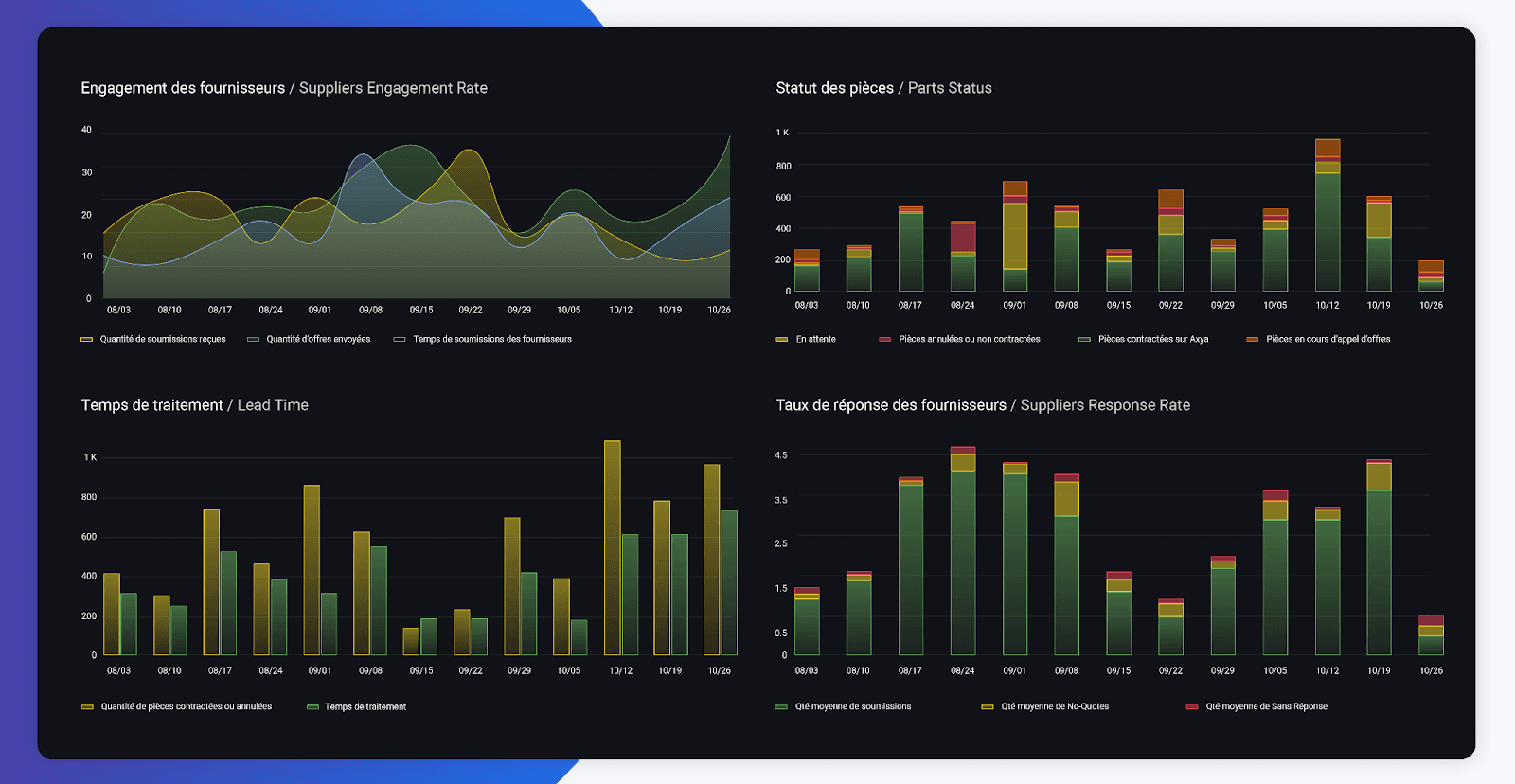

Now, Axya is able to provide OSI Machinery with 50 procurement KPIs that can provide quintessential information for future improvement through a dashboard that connects directly to their operational data. This gave them tools to track business level KPIs and to proactively know if any supplier is experiencing difficulties.

Example of 4 KPIs that we can track within the platform: supplier engagement, time to respond, status of request and response amount for suppliers.

A big part of the success of this deployment can be attributed to OSI’s drive to improve their internal processes for the sake of continuous improvement - They made the required changes internally to position Axya the best way possible within their tool stack and the users accepted with optimism the arrival of a new tool in their daily ops.

The value of data

OSI Machinerie stands out from the crowd-- not only for their state-of-the-art line of equipment and passion for innovation but also for their deep understanding of the importance of data. While many manufacturers may experiment with new suppliers or technologies, OSI Machinerie has used Axya to leverage data pragmatically in all departments of the business.

Even the company’s procurement team, a department that notoriously struggles with data visibility across many manufacturing companies, has managed to leverage key data and influence decisions the company makes for the future. OSI Machinerie’s procurement professionals use the platform in a predictive fashion-- analyzing data to find potential vulnerabilities and strengths within their supplier network ahead of time in order to achieve the best possible outcome.

« As OSI is a company focused on innovation in both its products and operations, we are constantly on the lookout for partners who share our vision.

We needed to automate and develop our supplier network, and Axya helped us achieve this.

The ease of implementation and communication with their platform, as well as their technical support, enabled us to integrate this solution easily and in record time.»

Frederic Maheux - Operations and Products Development Director

« The Axya platform saves us a lot of time when it comes to bid follow-up. It's easy to add relevant information, drawings and so on to the subcontractors and notify them all at the same time, which saves a lot of e-mail exchanges.

What's more, the fact that the bids are put into an Excel file makes it much easier to award contracts. Our purchasing team saved time and gained better visibility of all our requests. »

Alex Loignon - Operations manager

OSI Machinerie provides its customers with the tools to reach their full potential, all while being equipped with the best tools for themselves. Now at the forefront of companies leveraging data to improve their procurement processes, OSI Machinerie can focus on helping even more customers uncover efficiency and cost savings through innovative solutions and expert guidance.

For more information on OSI Machinerie visit their website.