Case Study

How Cemen Tech Reduced Their Late Deliveries by 52% With Axya

Oct 21, 2024

Company Overview

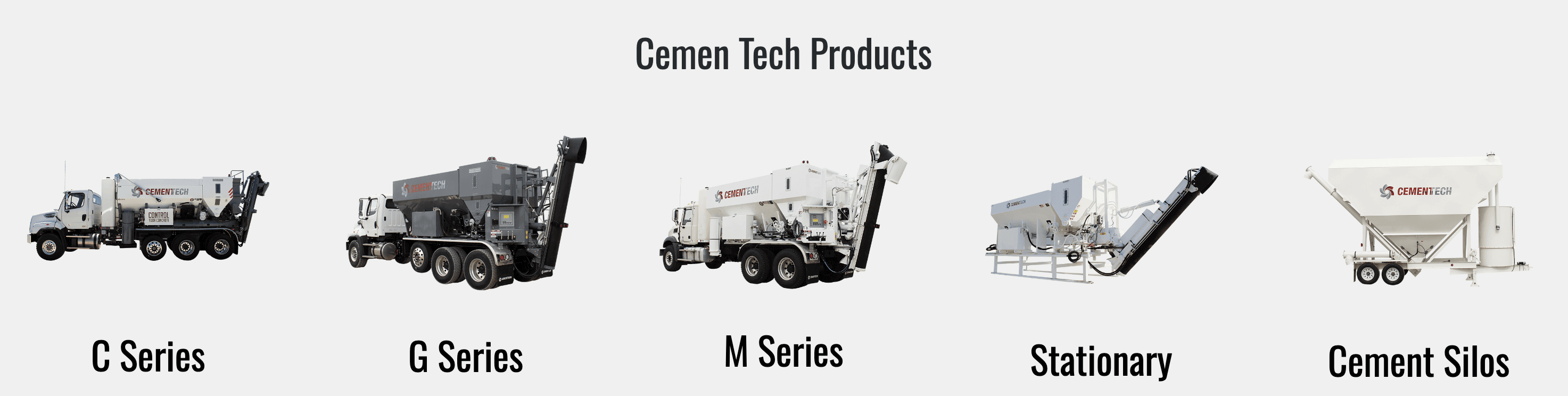

Founded in 1969, Cemen Tech is a world leader in volumetric concrete mixing technology. Based in Iowa, USA, the company designs and manufactures mobile and stationary volumetric concrete mixers, which allow customers to mix concrete on-site, reducing waste and increasing efficiency. Cemen Tech serves a wide range of industries including construction, infrastructure development, and military projects, and has a global presence, delivering its innovative solutions to over 70 countries.

Challenges and Issues

Before adopting Axya’s orders management module, Cemen Tech faced challenges in its procurement process. As the company experienced growth, it became increasingly difficult for the team to manage the rising volume of orders efficiently. Cemen Tech relied heavily on manual processes, which consumed excessive time and led to communication gaps with suppliers. As a result, there were delays in deliveries, inefficiencies in internal coordination, and missed opportunities for process optimization.

The company smartly identified several key areas that needed improvement:

Time Management: The procurement team spent too much time managing orders manually, leaving less time for strategic tasks.

Late Deliveries: The lack of visibility and manual tracking led to delays and missed deadlines.

Internal Collaboration: Coordination between procurement, engineering, and production teams was labor-intensive and prone to errors, which slowed down project execution.

Solution and Implementation

Choosing Axya’s Order Management Module

To address these issues, Cemen Tech decided to implement Axya’s Order Management Module. After an evaluation of various solutions, Cemen Tech selected Axya due to its compatibility with their existing systems Genius ERP and its ability to automate repetitive tasks, streamline communication, and improve internal and external collaboration.

In the first 10 weeks of usage, Cemen Tech had already sent over 1,300 orders through Axya’s system, signaling rapid adoption and immediate impact. The collaboration between Cemen Tech’s procurement team, led by Tracie (Purchasing Manager) and Brant (Supply Chain Director) and Axya’s team resulted in a smooth implementation process, and both sides identified further opportunities to increase value through KPI reporting, platform customization, and refining the solution for Cemen Tech’s unique needs.

Results and Benefits

1. Productivity Gains

The implementation of Axya’s orders management module led to significant productivity gains for Cemen Tech’s procurement team. By automating manual tasks such as orders revision, follow-ups, and tracking, the team was able to save up to 50% of their time previously spent on managing orders. This time-saving allowed the team to focus on more strategic tasks such as supplier relationship management and optimizing their supply chain.

Tracie, Purchasing Manager at Cemen Tech, noted that “Axya has significantly reduced the time we spend on administrative tasks, giving us more time to focus on higher-value activities that drive the business forward.”

2. 52% Reduction in the Volume of Late Parts

Axya’s automated workflows have enabled Cemen Tech to reduce the number of late parts recorded in their ERP system. By allowing buyers to quickly focus on delayed orders almost autonomously, the platform has greatly improved the accuracy of project timelines. This enhanced visibility has translated into more reliable internal project management, as ERP data is now more precise and up-to-date. As a result, Cemen Tech has seen a marked improvement in on-time project deliveries. Within just a few months of implementation, Axya empowered the procurement team to be more proactive in following up on orders, reducing the volume of late parts by 52%.

The solution also reduced data manipulation errors, which were previously a source of miscommunication and delays between buyers and suppliers.

3. Improved Internal Collaboration

One of the most significant improvements was in internal collaboration. Axya’s platform centralized procurement data and made it easily accessible across departments. This not only reduced the time required for internal coordination but also improved the quality of communication between procurement, engineering, and production teams.

Brant, Supply Chain Director at Cemen Tech, highlighted that “coordination with other departments has become seamless. We can now access information in real-time, which has reduced miscommunication and made collaboration far more efficient.”

Looking Forward

As Cemen Tech continues its journey with Axya, both companies are exploring additional enhancements, such as custom fabrication orders and KPI reporting to optimize procurement operations further, and improve risk mitigation strategies and supplier scorecard analysis. The early success of the orders management module indicates that future developments will bring even greater efficiency, transparency, and collaboration across the organization.

Conclusion

Cemen Tech’s implementation of Axya’s orders management module has transformed its procurement operations, significantly increasing productivity and improving both supplier management and internal collaboration. By automating manual processes and providing greater visibility, Axya has allowed Cemen Tech’s team to focus on more strategic tasks and reduced the likelihood of late deliveries.

In just a short time, Axya’s orders management module has proven to be a vital tool for Cemen Tech, driving substantial improvements in efficiency, communication, and overall operational success. The future looks promising as Cemen Tech continues to collaborate with Axya to optimize its procurement processes further.