Blog

Why you should track procurement RFQ processing time

Jul 19, 2022

The RFQ processing time represents the elapsed time between the moment a request for sourcing is internally received by the procurement team (often from engineering) and the moment the supplier selection is completed for the requested package and synced to an ERP system for further contractualisation steps.

In the manufacturing industry, 20 work days is usually a typical threshold used to know if a procurement cycle is on track or not. For this KPI, the shorter the cycle, the better since it directly impacts the ‘on-time delivery’ of parts.

The processing time can be split into 3 subsequent steps :

(i) gathering and submitting the technical information to the selected suppliers

(ii) suppliers taking the time to submit their offers

(iii) consolidating and analyzing the data to complete the make a strategic supplier selection.

3 steps of the processing time

Each of those steps can be measured and monitored independently and added together to result in the RFQ processing time. Segmenting these three steps gives much more visibility and allows you to monitor where the bottleneck is within your procurement throughout the months…

(i) Data transfer : Is the internal process between engineering and procurement efficient or delays are accumulating due to a bad information transfer?

(ii) Supplier quoting : Is your supplier network availability good or they are busy and you have a hard time getting the required amount of offer in a timely manner?

(iii) Decision making : Does your procurement team have the time to focus on what’s important or they are overwhelmed and can’t make strategic decisions on time?

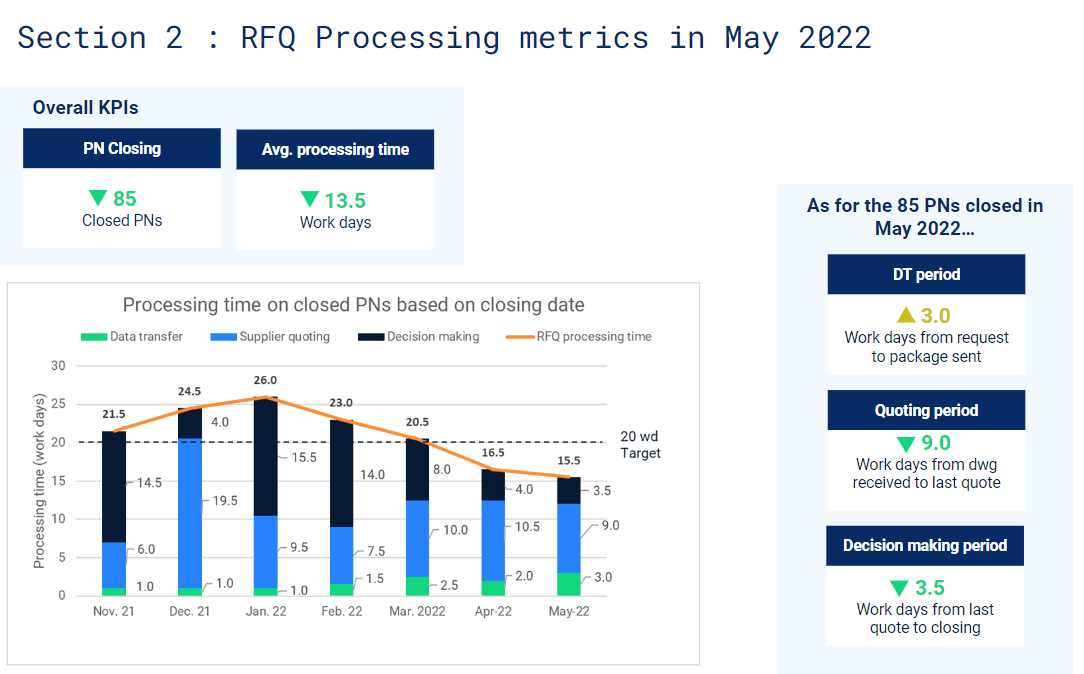

With a partnered manufacturer in the Aerospace industry, we implemented a strategy in early 2022 to first monitor and then reduce their RFQ processing time. The results were quite impressive!

The image above is an excerpt of a KPI report made to cover this subject with our partner in Aerospace. Data have been modified and anonymized. This is shown as reference only

We first realized that the supplier response time was fluctuating proportionally to their in-house availability. To manage those metrics, the client modulated the amount of suppliers targeted by adding 2-3 approved suppliers in the loop temporarily to compensate for their top suppliers' un-availabilities.

However, as shown in the image above, a large part of the processing time was allocated to the decision making period from the procurement team. The problem was that data was received through hundreds of emails, each with their own excel spreadsheets.

We realized that consolidating that data and knowing when an RFQ was ready for decision was the main bottleneck in that step. So here, the client was provided with tools to standardize their quote templates received by suppliers and visual dashboards to easily compare quote data. Also, we implemented a dashboard system for procurement teams to see their RFQs pipeline in real-time and have visual statuses indicating as soon as an RFQ was ready for analysis (i.e. 80% of suppliers had replied).

This reduced the processing time of that team by about 8 work days, which is a 30% time reduction achieved within a 1-2 months implementation plan.

Dashboard to check real-time RFQs pipeline

Next step is to optimize the supplier quoting period. Did you know that in those +/- 10 work days related to the quoting period, there’s about 3-4 days wasted due to un-efficient back and forth between the supplier and the buyer? More to come on this topic in my next post !

If this subject interests you, reach out to me! I would be glad to extend the discussion and know more about how you track your procurement KPIs and what challenges you are currently facing.

Alexandre Laliberté, Head of Customer Success at Axya, alexandre@axya.co