Case Study

Vention : World-class solutions through local networks

Jul 14, 2022

Learn more about how Vention was able to nearshore a portion of their supply chain during the midst of the pandemic!

Meet Vention, a platform with one simple mission of bringing ease and accessibility to the industrial automation process. “We envision a world where the process to build industrial equipment is as straightforward, and enjoyable, as building with LEGO,” states the company website. Since the company’s launch in 2016, the team has remained loyal to their roots in Quebec and the goal of simplifying the machine design process, all while growing their user base to 40 000 individuals across 3 continents.

Vention has used the Axya platform to streamline the sourcing process for custom metal factory parts. Having initially stumbled upon Axya in an effort to find a quick fix for a delayed overseas order, they soon began using the platform to build a network of reputable local suppliers for their complex manufacturing needs.

Recovering from the Unexpected

In the seven years since the company’s inception, Vention has developed a diverse suite of applications helping companies implement new measures, keep global teams updated on machine procedures and automate processes that previously required manual action. The company has also helped numerous companies adjust to an increasingly remote workforce with applications that enable users to deploy and manage machining processes remotely.

With such an innovative and vast range of applications, the Vention team braced themselves to help their users adjust their production processes amidst global COVID-19 lockdowns and ensure that companies could continue with as much of their production processes as possible.

In their pursuit to help customers stay in production, the Vention team found that they were facing numerous delays on orders for various metal parts. With their supplier being based overseas in China, Vention knew that the pandemic would likely present them with delays and no simple way to source overseas parts for the near future. Seeking a solution, they turned to Axya, posted their RFQs and received 16 local quotes within 4 days, each more competitive than the previous one.

The Hidden Gem of Local Production

Despite its global network of users, the Vention team has embraced the hidden strength of local networks-- especially in times of uncertainty. Through helping many users manage their complex supply chains and advanced automation processes with new technologies, Vention has witnessed first-hand the vulnerabilities of global supply chains. From varying time zones to communication barriers, Vention knew that searching for alternative solutions was a priority as the global manufacturing industry became increasingly vulnerable and volatile.

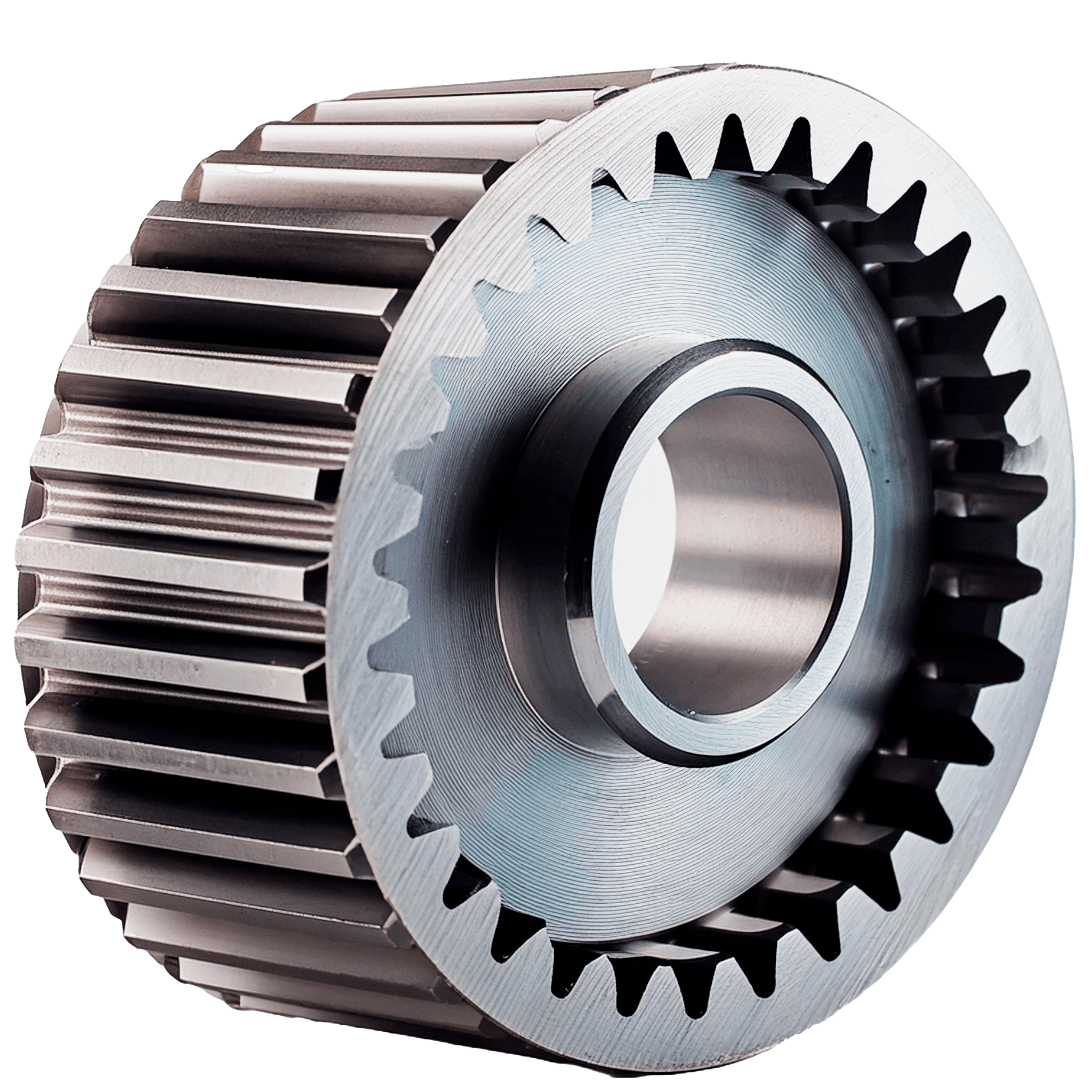

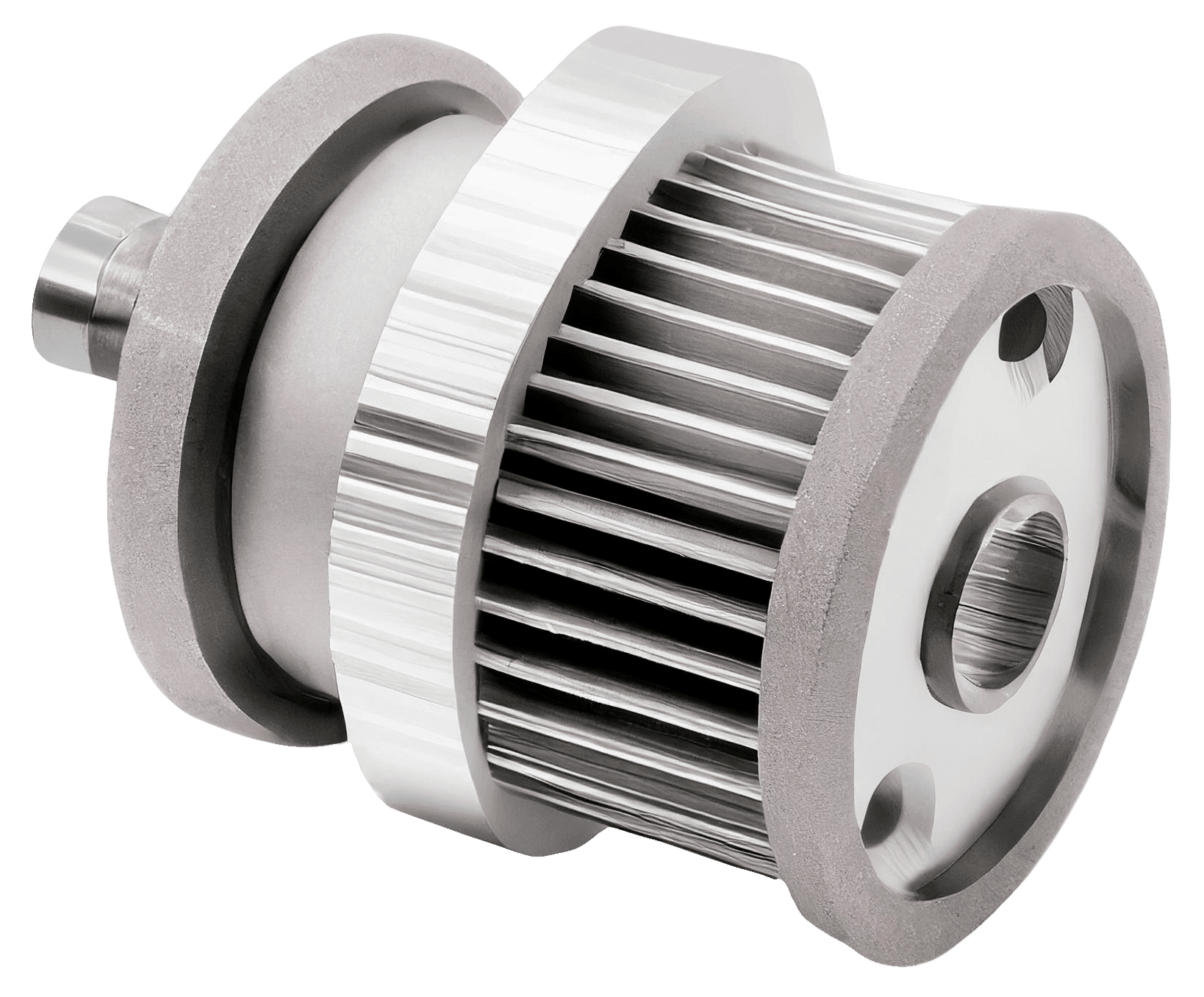

Using the Axya platform, Vention discovered the strength in local production. Requiring parts that involved numerous fabrication processes such as machining, anodizing and engraving along with the capability to provide storage services, Vention was impressed to find Quebec-based manufacturers who were capable of managing all parts of production for their complex metal factory parts.

According to their Supply Chain Director, Vention has prioritized local production and managed to continually receive competitive bids since discovering Axya-- all with faster delivery, less hassle and easier communication.

“Had we seen this finish before, we would have treated all our parts like that,” he adds.

Building a Strong Network

As a company serving customers all around the globe, it’s no surprise that Vention has an extensive network of international suppliers. Vention continues to cement its status as a global leader in the industrial automation industry as it grows its user base, range of applications and company size. Despite this impressive global network, Vention’s team knew of the incredible strength in their Canadian roots and was determined to learn more about the growing manufacturing industry located right at home.

Thanks to Axya, Vention has been able to establish long-term relationships with several Quebec-based manufacturers located minutes away from Vention headquarters. What initially began as a search for a solution to a delayed order has now flourished into several new supplier relationships and a strengthened professional network. Vention now regularly leverages the strength of local suppliers and is eager to continue supporting the world-class capabilities of manufacturers on Canadian soil.

Embracing Innovation

Now entering their seventh year of operations, the Vention team understands that it is more crucial than ever to continually seek out the most competitive processes, partners and solutions in order to grow. Having added numerous new applications over the past few years to help users adjust to an increasingly remote and automated world, Vention has truly embraced innovation and sought out new solutions to navigate these ‘new normals’.

When a company is innovative and dynamic as Vention, its networks and solutions must be continually adaptable. After using Axya to establish a robust Canadian supplier network, Vention is now better equipped to deal with unprecedented circumstances that the future might bring.

With hopes to continue revolutionizing the industrial automation industry, Vention knows that the Axya platform and supplier network will continue to help them as they continue with their mission to bring ease and accessibility to users everywhere.