Case Study

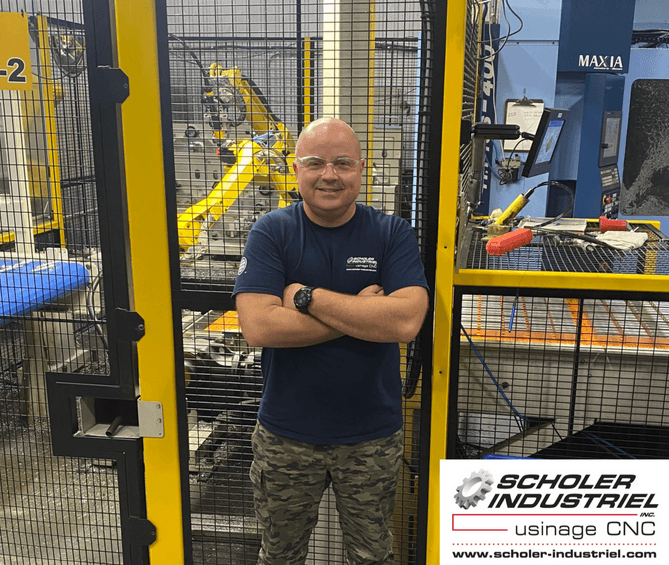

Scholer Industriel: Machining Innovation at Your Fingertips

Feb 6, 2024

Taking the leap and adopting automation in production can often help teams reap numerous benefits. From saving time to being able to take on more advanced projects, these changes allow these partly automated machine shops to push the limits of their capabilities and stand out amongst the crowd.

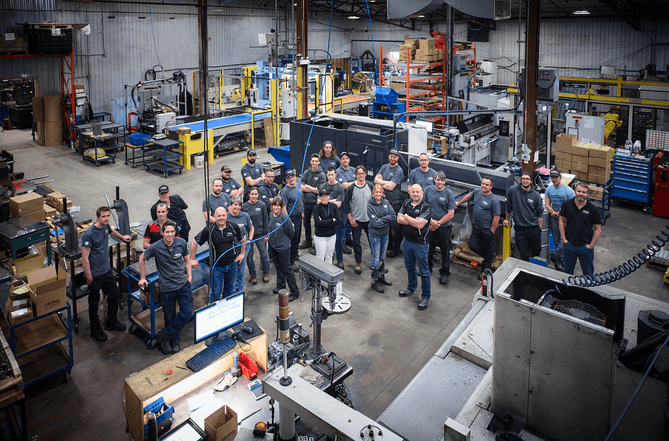

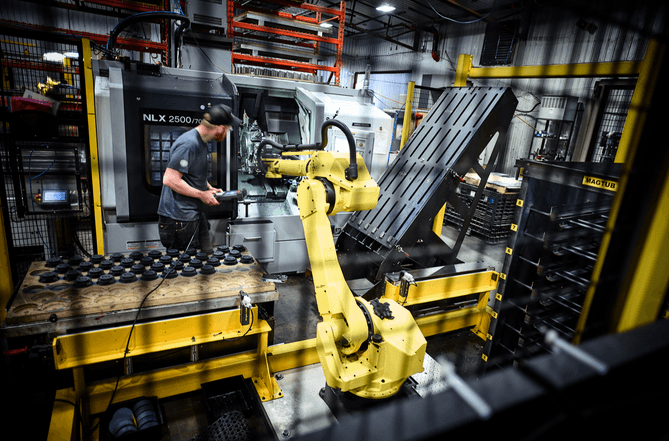

Take Scholer Industriel as a shining example of this phenomenon. The Magog-based manufacturer has equipped nearly half of its machines with automated capabilities-- enabling the team to increase both efficiency and capacity. Thanks to their decision to automate, the shop’s team has also managed to achieve the unique feat of running their production around the clock, thus easily adapting to the needs of their ever-growing client base.

An Eye on Precision and Quality

With a shop floor of over 26,000 sqft in size, Scholer Industriel is home to some of the country’s leading technologies in precision machining-- including 17 numerically controlled machining (CNC) centers (of which 7 are fully automated). The team also offers services in milling, turning, CAD drawing and robotization.

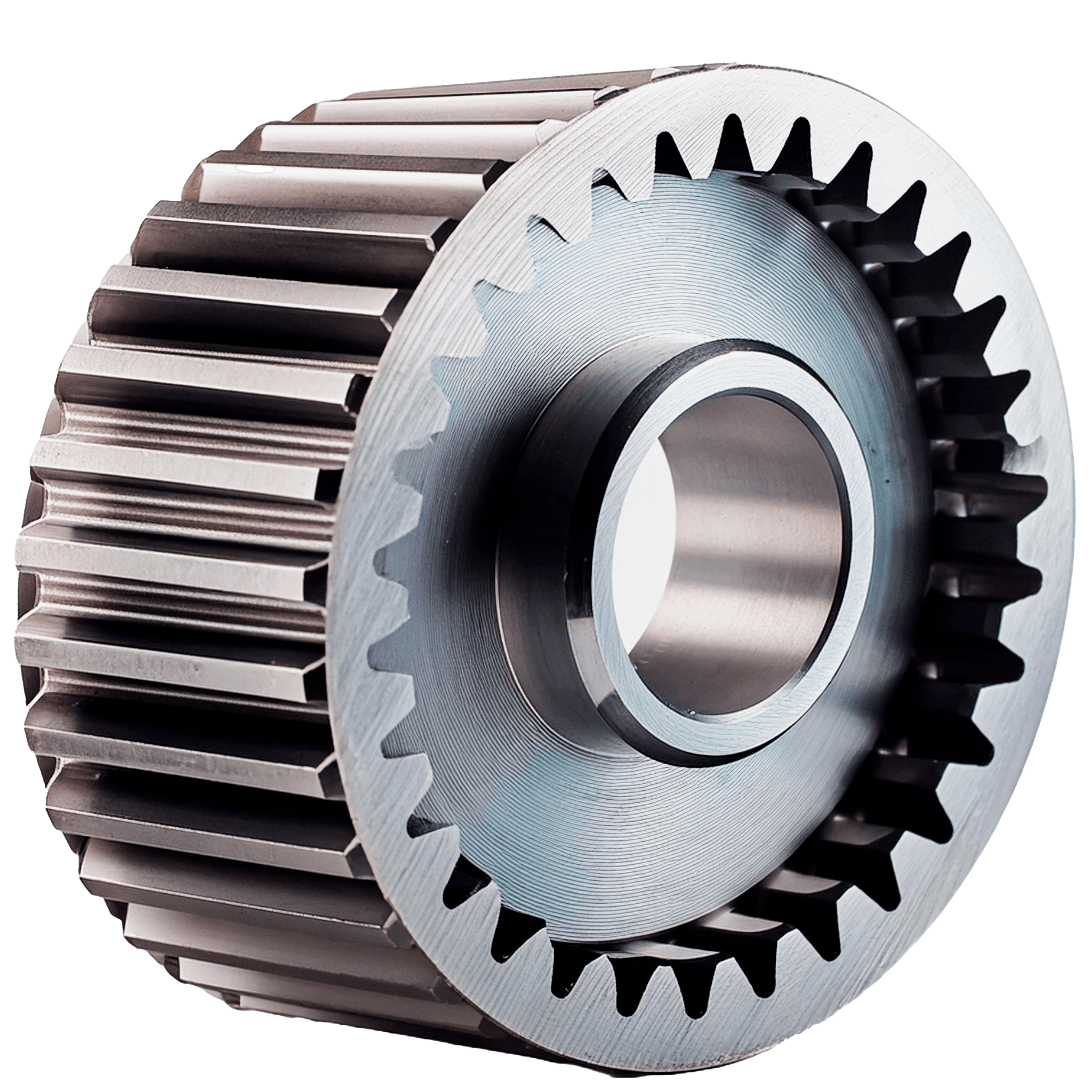

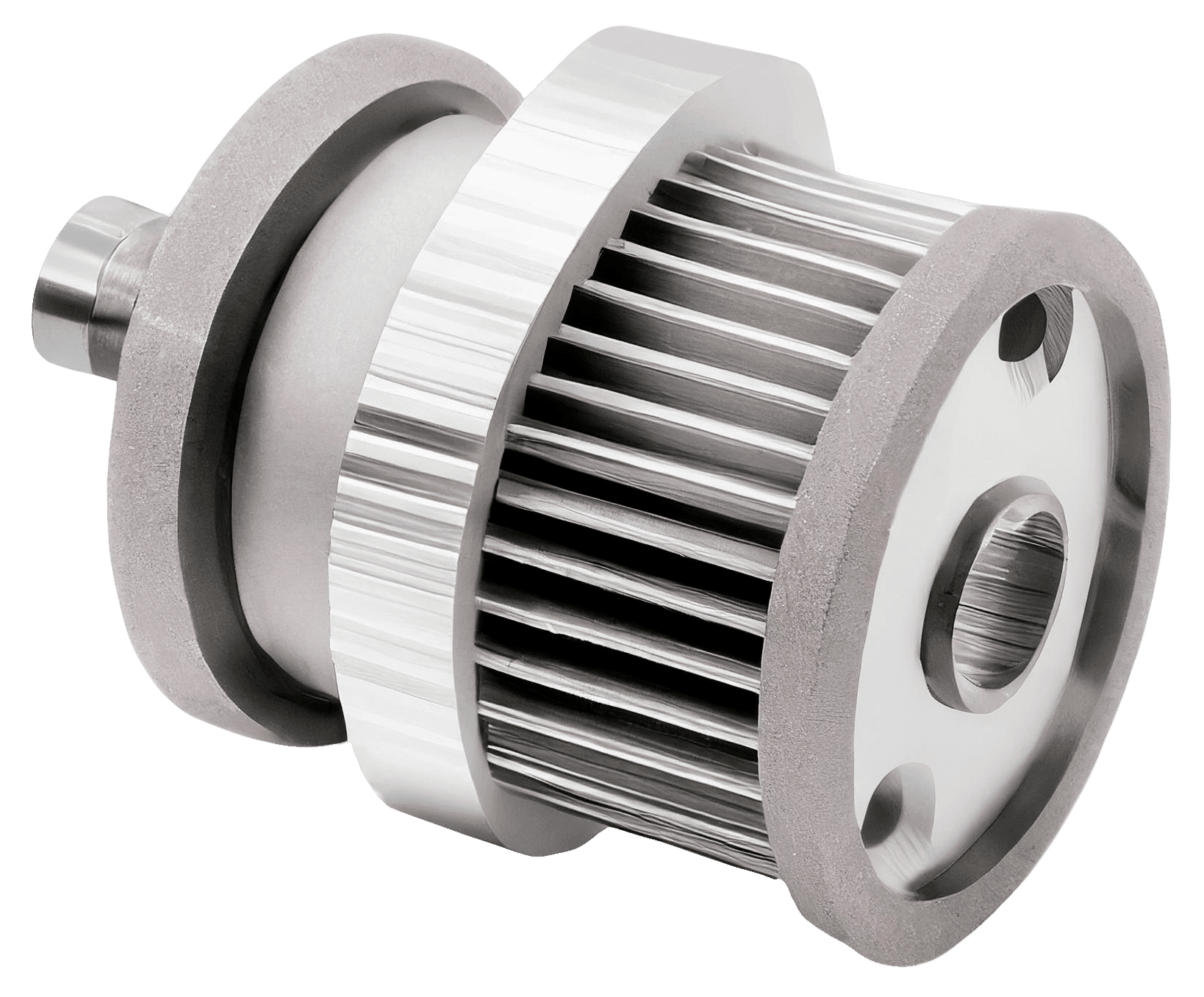

As proven by their investment in automation, the team at Scholer Industriel holds immense pride and passion for quality and production excellence-- constantly striving to set the industry standard for speed, precision and cost. The shop’s ability to manufacture parts with high complexity and precision up to 0.005mm further ensures the shop’s customers that they have a trusted business partner for projects seeking even the most complex and unique machine parts.

Scholer Industriel further demonstrates its commitment to quality standards through its industry-certified quality control processes. The shop is compliant with ISO9001 :2015 and is currently in the process of acquiring its AS 9100 certification-- a set of standards which encompasses quality and safety standards for companies working with clients in the aerospace industry.

Leading with an Innovative Vision

Behind Scholer Industriel’s innovative excellence is none other than Christian Coupal, the company’s current president. After completing his studies in mechanical engineering at CEGEP de Sherbrooke, Christian began his career in the aerospace industry-- an experience which provided him with first-hand insight into the complexities involved in the production of aerospace components. While pursuing his MBA three years later, he simultaneously worked with Scholer Industriel and learned the ins and outs of the company from none other than shop founder Marc-Etienne Scholer.

Having served the company for a decade, Christian knew that he wanted to integrate automation into company operations as he assumed the role of company president in 2008, combining his knowledge in both engineering and management to lead Scholer Industriel through a new era in machining. As he witnessed other manufacturers begin to implement new machining technologies, Christian created a long-term strategic plan for Scholer Industriel’s modernization in an effort to remain resilient for decades to come.

The company acquired their first robot in 2014, integrated with an ERP in 2016 and in 2017, made a significant investment into robotization and automation of its factory. In 2018, Christian spearheaded the establishment of the company’s autonomous robotics team-- solidifying its position as a trailblazer in the realm of highly automated precision manufacturing and forming the Scholer Industriel that we know today.

Supplier Excellence: Going Above and Beyond

Scholer Industriel has built up a diverse clientele from demanding industries such as medical, transportation, energy, and soon aerospace. With a spotless track record of delivering excellent services to leading companies, the shop has repeatedly proven to be a dependable partner that customers can entrust with their most complex projects.

Scholar Industriel complete profile can be consulted over here

Despite their constantly growing customer base, Scholer Industriel’s team never lets their production quality or excellent customer service waver. As a supplier on the Axya platform, Scholer Industriel continues to serve buyers across Canada-- taking on both ad-hoc requests from customers looking for one-off parts too complex for their existing suppliers and long-term production partnerships for recurring parts. Buyers can further rest assured knowing that their production projects are in good hands all the way from ideation to end-product delivery, offering comprehensive assembly services in tandem with machining to ensure precision from conception to completion.

Scholar Industriel can be easily found through our free supplier directory tool to find capable manufacturers (Register here)

For those looking to manufacture complex parts, Scholer Industriel, stands as a reliable partner. The combination of a state-of-the-art machine shop, a customer-centric team and a relentless drive to innovate positions them as an exciting force in the industry that not only meets the demands of today but anticipates the challenges of tomorrow.

To contact Nicolas Fauret from Scholer you can email him at nicolas-faure@scholer-industriel.com, call him at 819-843-1065 or visit his Axya profile for more information.