Case Study

Laserax : High Performance Laser and Supply Chain

Jul 26, 2023

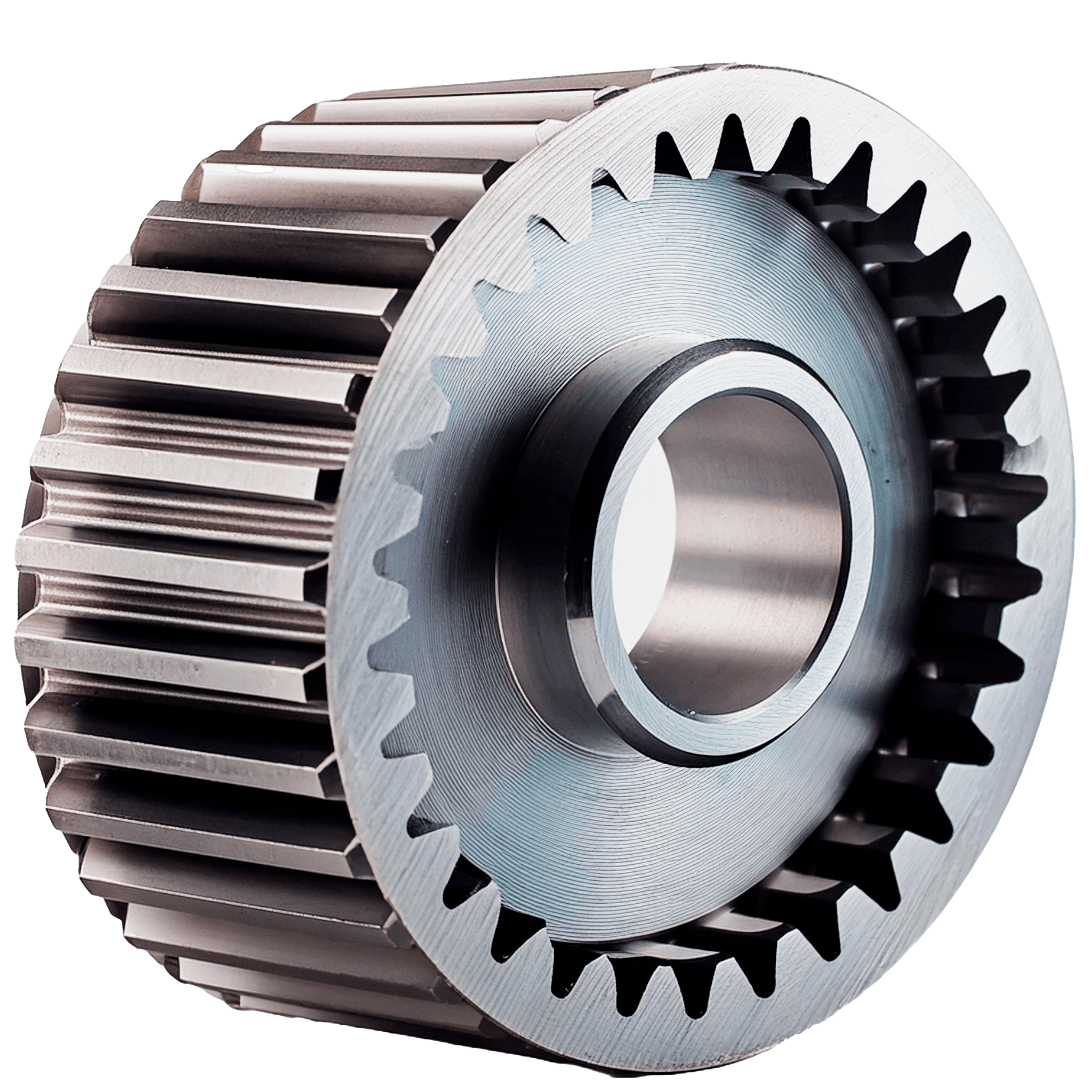

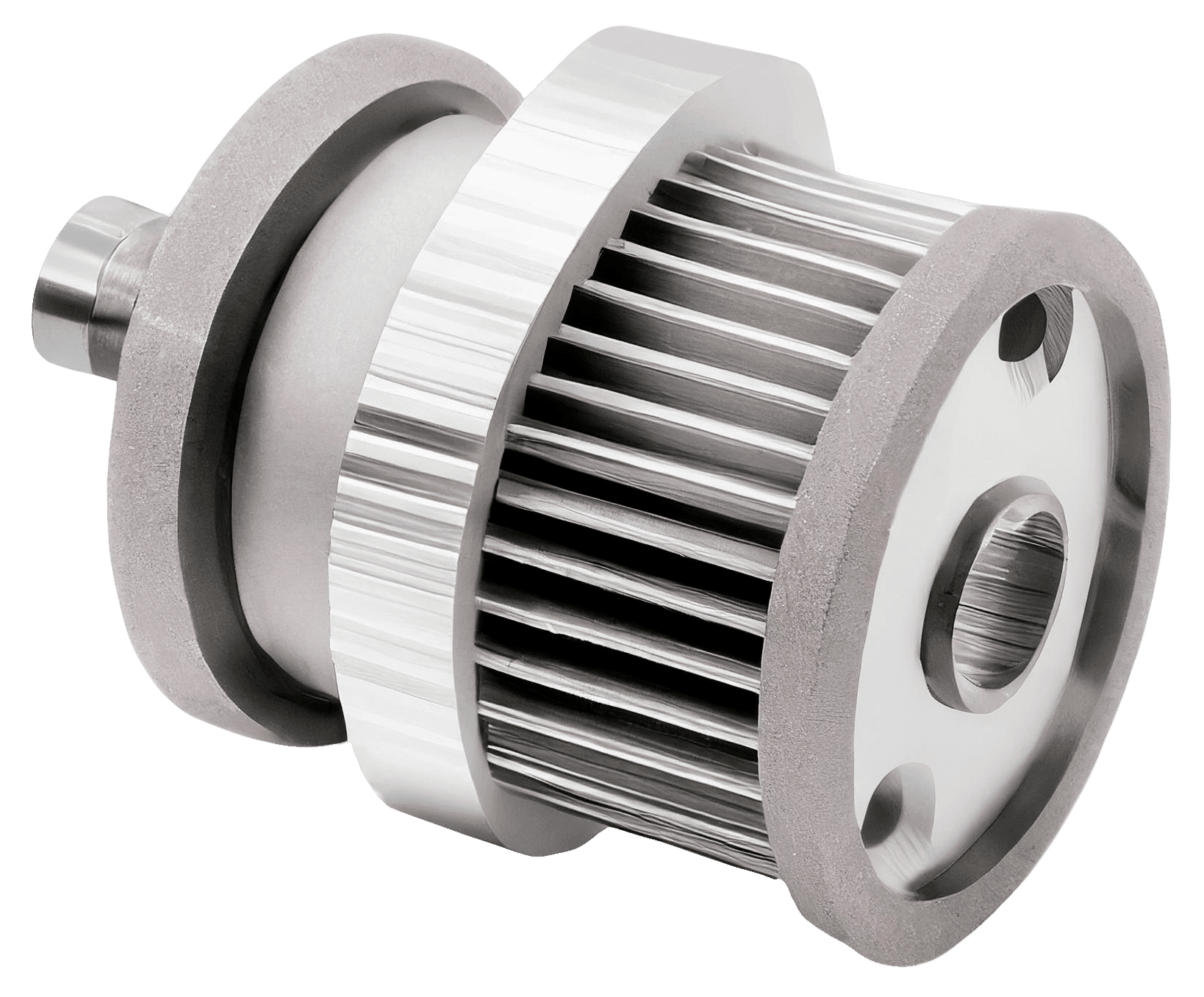

Laserax’s high-performance laser systems can be found in the facilities of the brands we interact with on a daily basis. The company specializes in the production of laser markers, cleaners and welding machines that allow manufacturers to increase precision and assure quality in the production process. The company serves a plethora of clients in industries such as electric vehicles, battery production and agricultural equipment.

Laserax offerings include turnkey machines and OEM systems -- catering to the likes of manufacturers of varying experience levels with laser equipment. In recent years, many industries have invested significantly in laser technologies due to their increased productivity, lower operating costs, and consistent results. With more and more companies participating in this shift, Laserax is well on its way to show the world all that laser technologies have to offer.

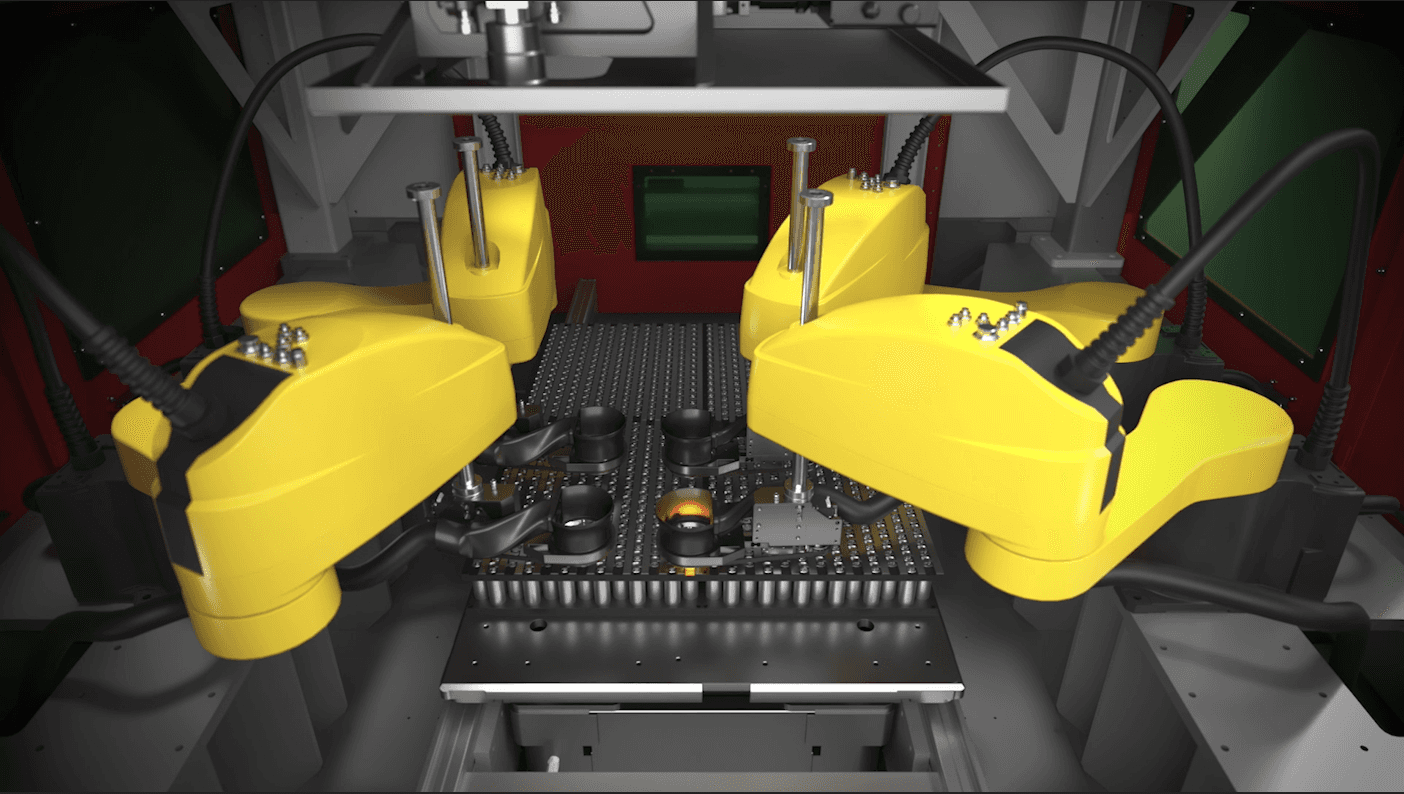

Automated Industrial Battery Laser Welding Machine by Laserax

Expanding the horizons of laser equipment

Although Laserax has only been in operation for 13 years, the company has already made a significant impact on the worldwide laser equipment industry. The company initially focused on creating inline laser solutions for large smelting plants but later expanded its services to include casting plants and automotive part suppliers worldwide.

Laserax Headquarters in Quebec

Originally founded in Quebec City, Laserax has now grown to include locations in the United States and Germany. They have also partnered with various companies in more than 15 countries to offer their efficient technologies to international consumers. Several Laserax clients have cited the company’s monumental role in helping them achieve safer, simpler and more cost-effective production processes.

A custom approach to equipment

Since 2010, Laserax has experienced significant growth in its client base. However, the company's pride still lies in providing comprehensive and tailored solutions to each and every new customer. During client consultations, the team optimizes current lasers, plans for and installs new ones, and conducts multiple rounds of testing to ensure that customers receive proper support and training. Above all, Laserax’s wealth of automation expertise allows the company to provide the fastest lasers in the industry (when benchmarked against those of competitors).

Laserax's solutions showcase their dedication to sustainability and assisting customers in achieving energy efficiency and waste reduction goals. The company’s laser solutions help clients in the electric vehicle industry to manufacture battery modules with solutions to first clean cylindrical cells to remove contaminants before they’re being laser welded to the module’s busbar. The module’s housing is then laser textured to improve the adhesive’s bonding when sealed. These processes simplify the production and promote the shift towards sustainable transportation. Thanks to laser cleaning, welding and texturing technologies, companies are also able to revitalize consumables in the production process and reduce the amount of waste associated with manufacturing.

The multifaceted role of procurement

With a wide array of clients including Lion Electric, BRP and Rio Tinto, Laserax has undoubtedly made a name for itself as a trailblazer in laser equipment technologies. As their client base continues to grow, the team is constantly on the lookout for ways to help as many companies as possible discover the efficiencies made possible by lasers. In order to grow without sacrificing the company’s personal and detailed approach to each client, Laserax’s team knew that they had to be committed to efficiency in every aspect of the business.

On the procurement side, Laserax recognized the need to enhance their procurement processes and ensure seamless supply chain operations as they dealt with purchasing numerous custom parts for each tailored solution. Despite procurement departments often being brushed over when picturing manufacturing companies, these teams are tasked with an array of responsibilities including managing relationships with multiple suppliers, tracking performance, managing communications, negotiating and more.

Upgrading Laserax Strategic Sourcing

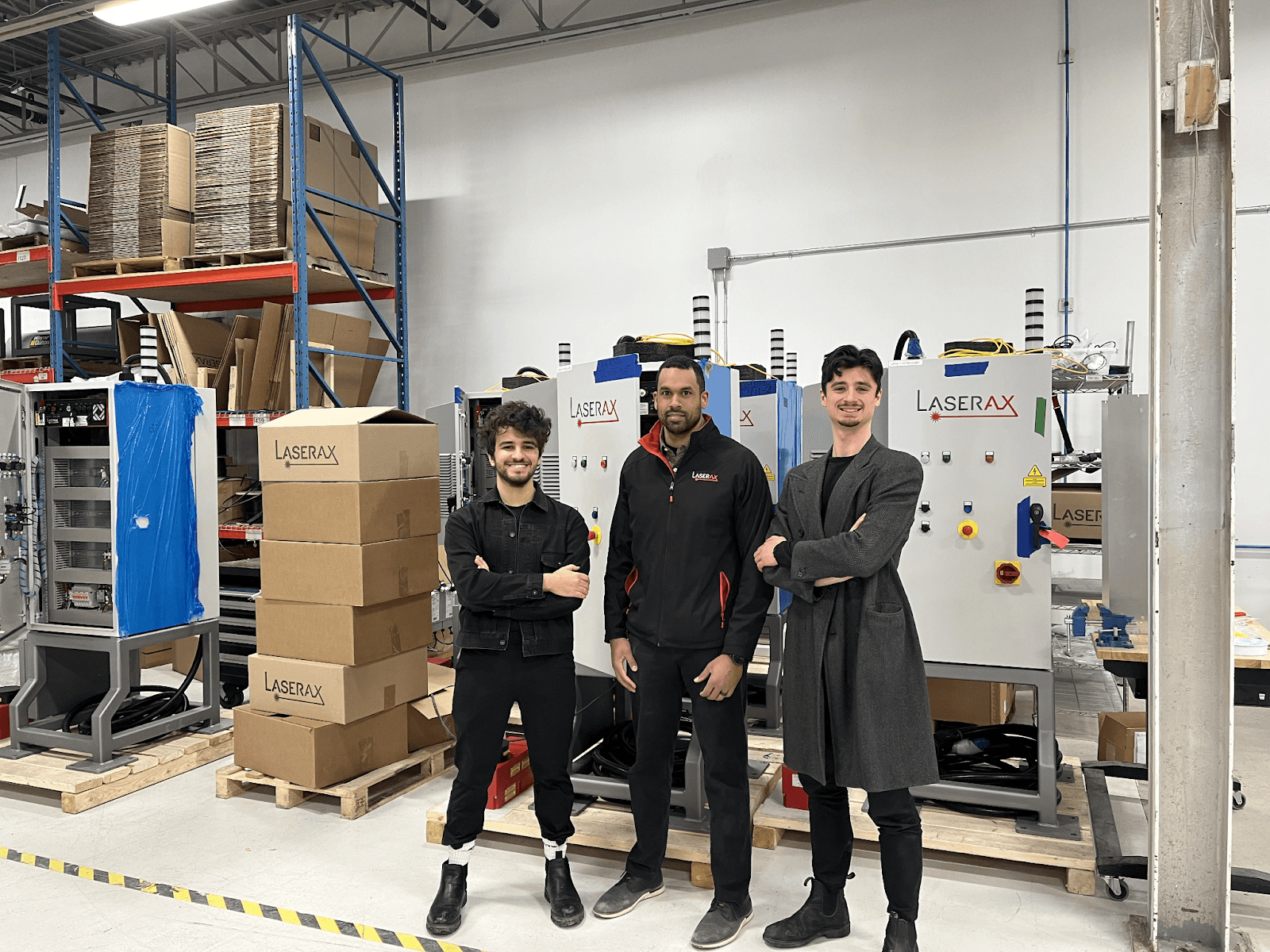

At Laserax, procurement professional Nathaniel Smith knew there had to be a way to bring efficiency to the procurement process too. He improved the procurement process by leading his team to use Axya’s RFQ Module. The software has since enabled them to centralize information shared between Laserax’s procurement professionals and their extensive supplier network.

Nathaniel Smith - Buyer at Laserax with two co-founders of Axya

The buying team additionally highlights the ease of using Axya to increase visibility on historical pricing for recurring components. This historical data provides procurement with the ability to target the best suppliers when ordering recurring parts in the future.

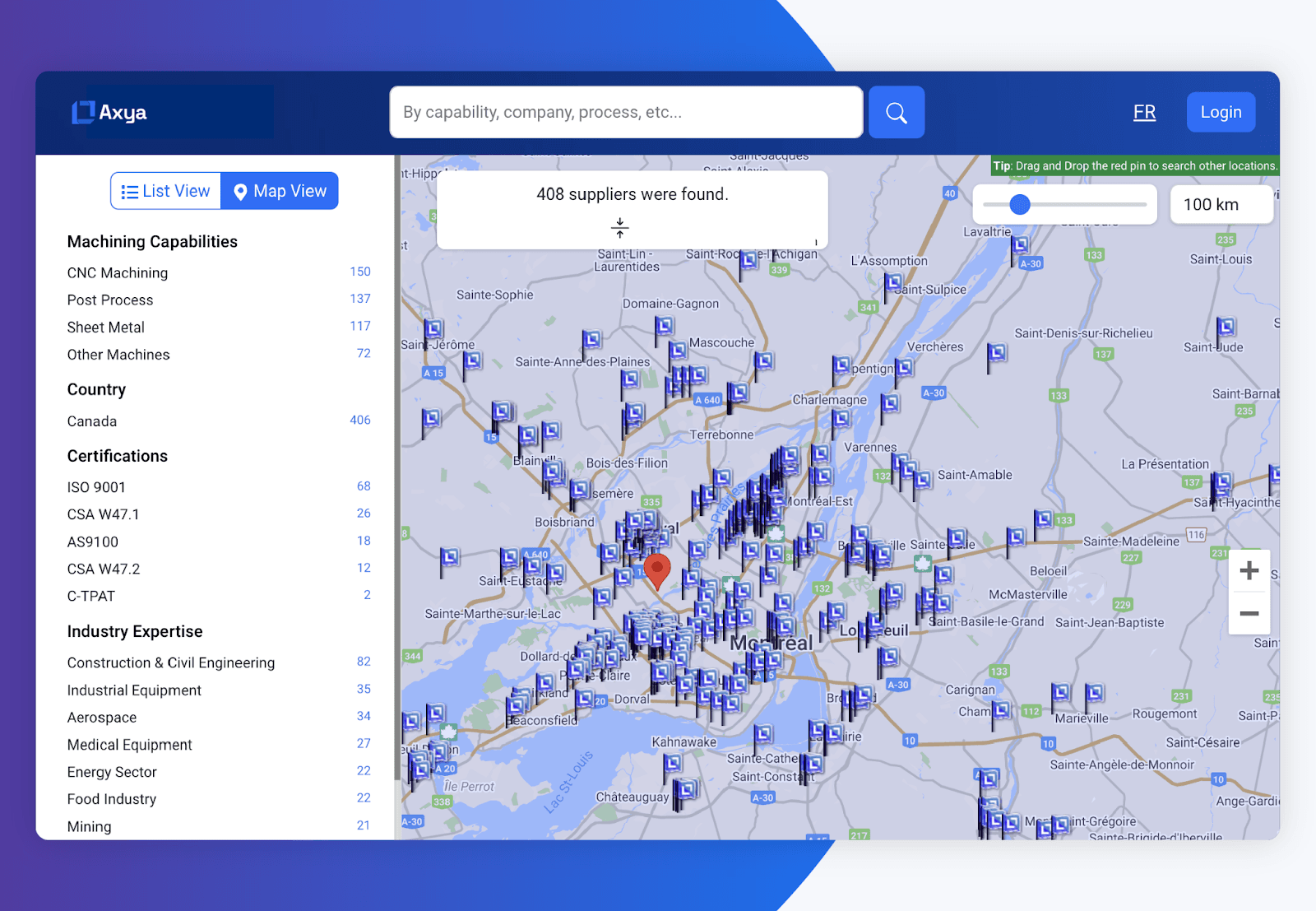

Furthermore, Laserax’s team has managed to adeptly maximize their use of the Axya platform by using it to discover local suppliers and connect with companies outside of their existing business network. With this feature, the team has been able to become more resilient in the face of unprecedented events and can be assured that they have the ideal local partners to collaborate with on projects involving tight deadlines or highly customized parts.

The directory allow Laserax to easily filter manufacturers and select interesting partners

In addition to being a time-saving tool for RFQ management and supplier evaluation, Axya facilitates the development of manufacturing relationships.

Nathaniel Smith - Buyer

Nathaniel Smith achieved impactful results for Laserax by generating savings of up to 20%. On top of direct savings on key components, the diversification allowed Nathaniel to better manage quick turnaround ad-hoc requests (i.e. R&D, Tests, BOM changes, etc.) that Laserax’s main suppliers didn’t want to handle.

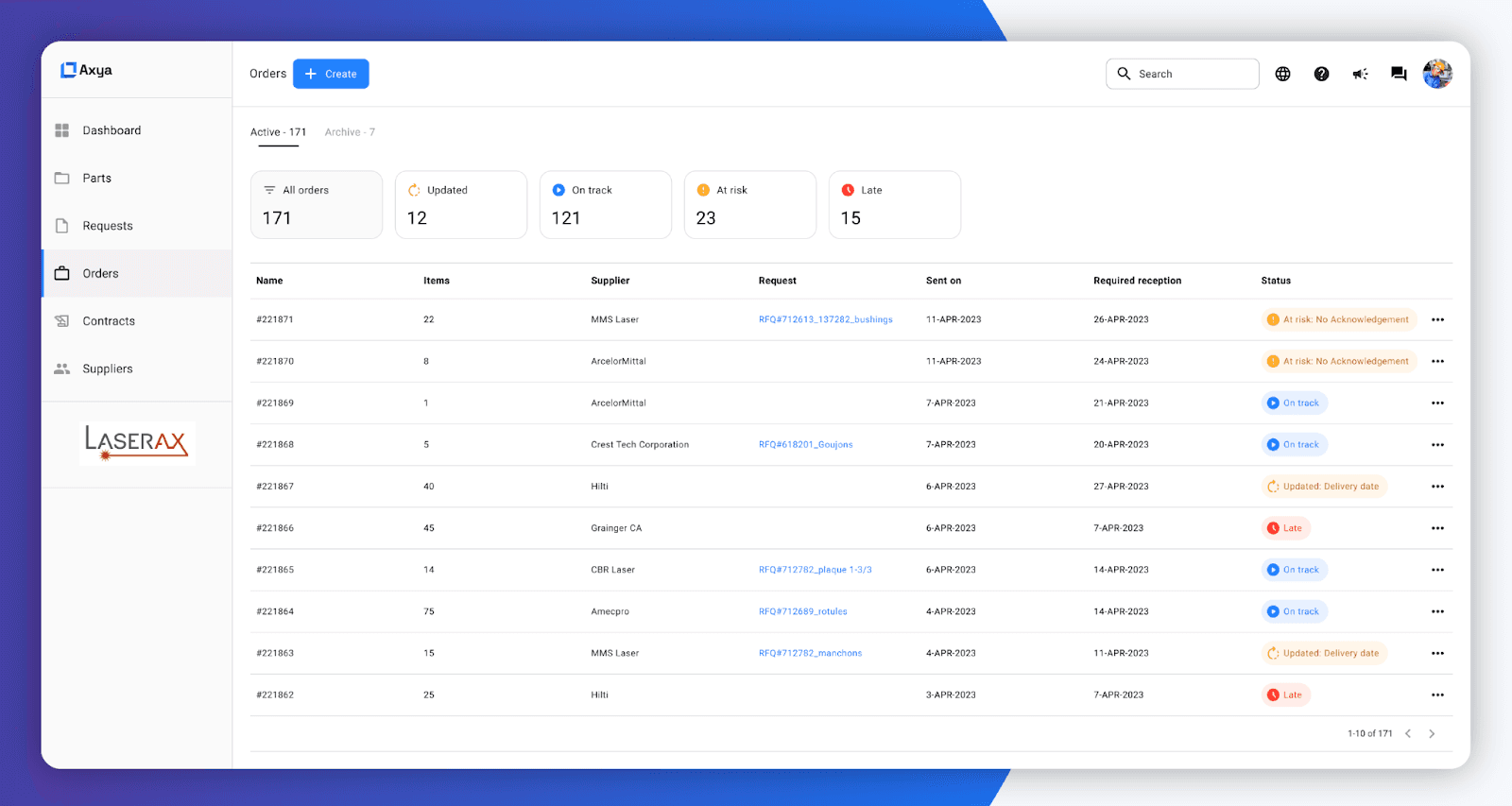

Optimizing Laserax PO Management

Finally, Laserax was part of the first companies to gain access to Axya’s PO Management Module back in April 2023. The buying team at Laserax handles more than 100 POs per month and they had a hard time keeping track of their statuses in an efficient manner.

The goal of implementing Axya’s PO Management Module was to improve the efficiency of the buyers instead of relying only on growing the headcount. In just 3 weeks, they deployed the solution and were able to track 100% of their POs - from their supplier’s acknowledgement up to shipping with the tracking number.

Within the first 2 months of usage, more than 160 POs were sent to 30 different suppliers. The buyers at Laserax now save a lot of time by not having to manually follow-up on orders and by easily being able to find the statuses of any part numbers they might need to dig into.

Example of the PO Management Module Dashboard to manage ongoing orders

Laser-Focused on Procurement Efficiency

Axya has enabled Laserax to gain a comprehensive understanding of the importance of strengthening its global supply chains. With time now freed up from managing communication streams and other manual procurement processes, Nathaniel and his team are now able to plan proactive measures to make the outsourcing process more robust for the future.

Equipped with the right supplier data and the tools to grow its network, the company can stay focused on its mission of helping customers work toward a more safe, sustainable and efficient future.

For more information about Laserax, do check out their website