Case Study

Flight to Success: Avior Integrated Products' Innovation Journey in Aerospace Manufacturing

Apr 18, 2024

In the world of aerospace manufacturing, precision and innovation are paramount. For over 20 years, Avior Integrated Products, a Quebec-based aerospace manufacturer, has upheld these values as a core part of its mission.

Having started as a Tier IV supplier of sheet metals back in 2002, the company has since evolved into an integrator of lightweight structures and flight-critical mechanical assemblies. The company accredits this transition to strategic acquisitions and investments in new technologies and talent as a large part of its continual success.

Example: the Avior team delivering the 1500th Bell 407 Swashplate to Bell Helicopter

Today, the company boasts a collective workforce of over 200 professionals and a manufacturing space of over 150,000 square feet in size-- across the company’s 3 business units. Its client base includes top aerospace industry clients such as Bombardier, Boeing and Airbus-- relationships that wouldn’t be possible without the company's keen dedication to precision, innovation, and efficiency.

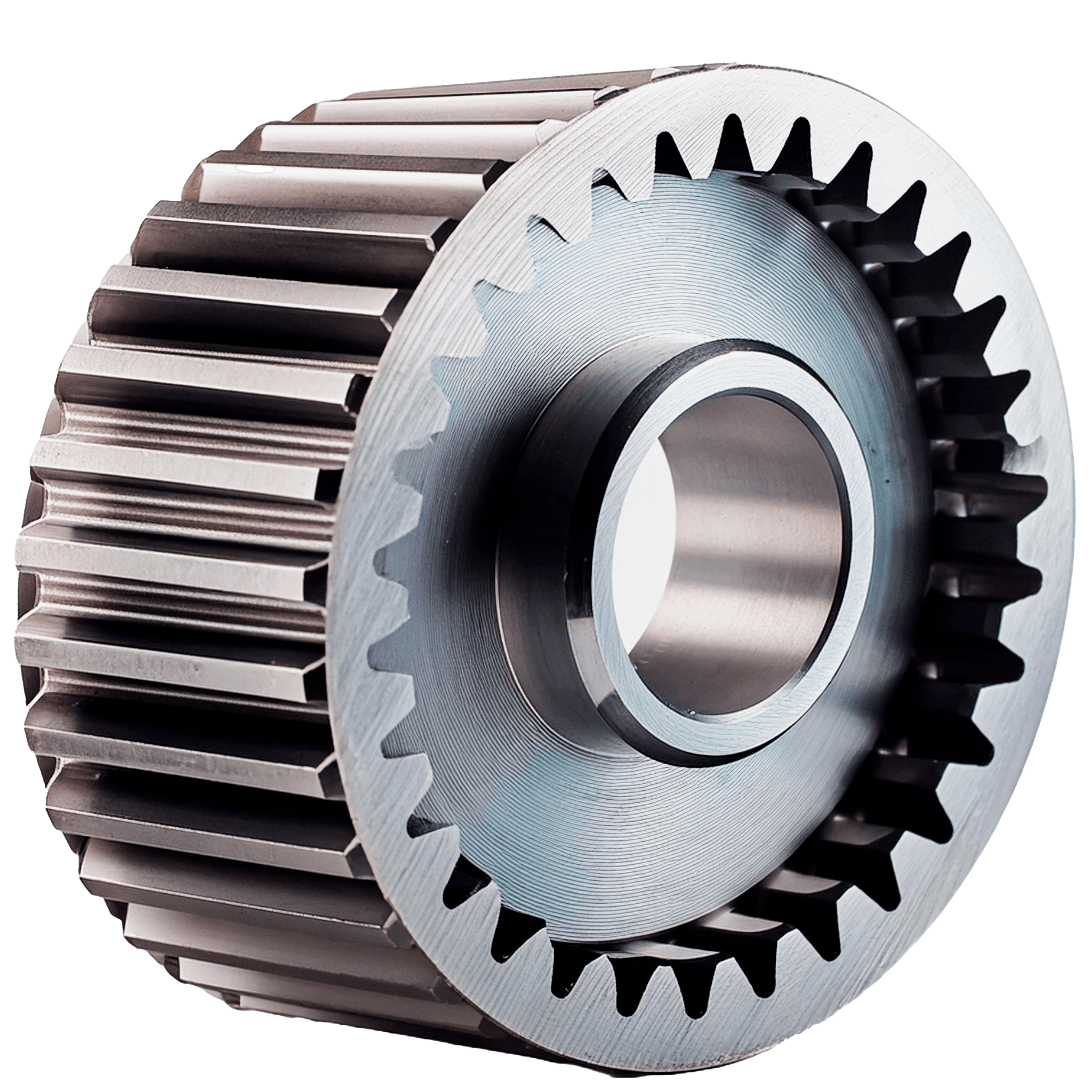

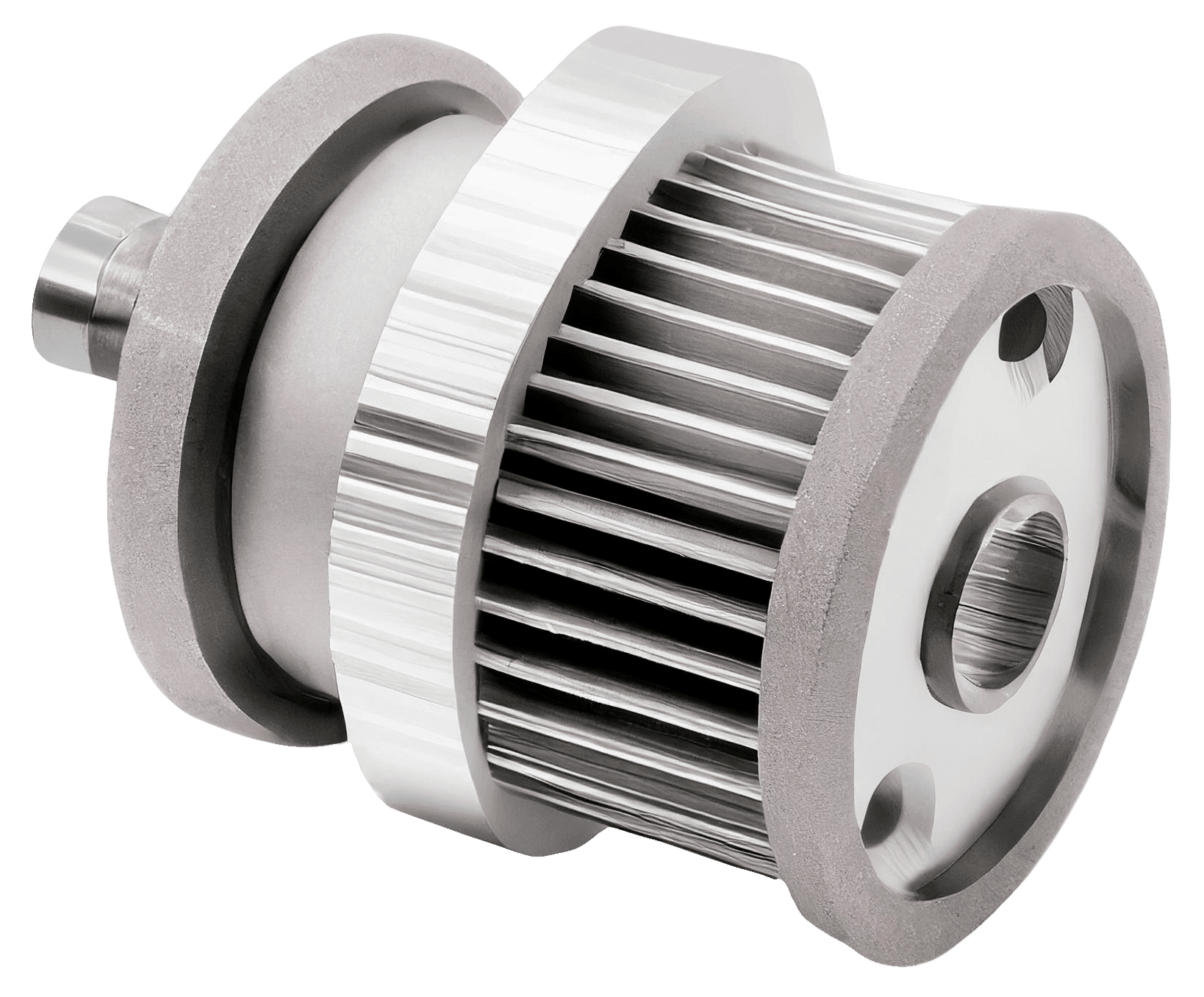

A world of in-house production capabilities

Avior specializes in the full-service manufacturing of hybrid lightweight structures and complex mechanical assemblies. The team produces flight-critical assemblies using frozen planning as well as structures that perform in high-temperature engine environments to ensure that all parts are manufactured to the highest quality standards.

The company offers complete in-house fabrication-- providing customers with a fully integrated one-stop solution that further allows for competitive pricing and reduced risk in the manufacturing process. This process enables Avior to maintain a high-quality performance track record as all aspects of fabrication are controlled by their team.

Example: Avior Produits Intégrés has set up a robotized cell to manufacture complex parts.

The team is skilled in a variety of machining processes-- CNC machining for medium-sized structural components, sheet metal fabrication for hydroforming and brake parts, and numerous other specialized processes. Their facilities are also home to an internal heat treatment center, a chemical processing line, and a fluorescent penetrant inspection line-- extremely specialized and highly integral parts of the aerospace manufacturing process.

Trusted by the industry’s best

Alongside its array of in-house manufacturing capabilities, Avior also takes immense pride in its state-of-the-art aerospace testing lab. Initially established to cater to internal production requirements, this cutting-edge facility now extends its capabilities to serve all customers, offering a comprehensive suite of materials testing, non-destructive testing (NDT) and destructing testing services.

With a wide range of approvals from industry giants such as BellFlight, Bombardier, Boeing and Airbus, Avior’s laboratory is equipped to conduct a diverse array of tests, all while empowering its customers to navigate the complexities of aerospace manufacturing with confidence that their projects are in the hands of the industry’s best.

Example: This robotized cell operates 20 hours a day, 7 days a week, to manufacture complex parts.

Further investments in innovation and technology have cemented Avior’s gold-star reputation in aerospace manufacturing. The company established its Automation Center of Excellence (ACE) in 2019 as a dedicated hub for pioneering new technologies and driving transformative change across its manufacturing facilities. Operating independently from regular production demands, the ACE is staffed by a team of talented engineers tasked with developing innovative solutions to enhance efficiency, reduce costs and provide competitive advantages for customers.

From robotic cells for machine loading and unloading to portable paint touch-up systems, ACE projects are driven by a singular goal-- to push the boundaries of innovation and deliver tangible value to customers. Thanks to its ACE initiatives, Avior was honoured with the Industry Excellence for Small Business Innovation technology by the Aerospace Industries Association-- proof that the company’s steadfast commitment to innovation is making ripples across the aerospace industry.

Example: Centre d’excellence en automatisation (ace)

Navigating the skies of procurement efficiency

With the wide range of services Avior offers to its clients, numerous procurement activities occur daily to feed production. From raw materials to hardware and perishables, the company manages hundreds of RFQs each day-- each with varying parameters and quality standards.

In tandem with the company’s relentless pursuit of innovation, Avior uses Axya to manage its procurement processes. The company leverages Axya’s RFQ management solution to get the optimal prices from their large network of approved vendors in the fastest time possible, thus allowing their ERP planner to quickly begin exporting their material needs.

Strategic Sourcing Module, allowing procurement professional to follow their procurement activity. This image shows no actual confidential information and is for illustrative purposes only.

Axya enables the team to compare several complex quotes with simple-to-use comparison tables to ensure that they can continue providing customers with the lowest prices possible. With Axya’s platform for standardizing the steps of the RFQ process, Avior effectively manages communication across several business units-- fostering visibility and collaboration.

Driven by their culture of innovation, the team has also used Axya to accumulate and track data on sourcing activities-- keeping up-to-date records on supplier performance that can be crucial when choosing suppliers for future projects and unlocking new efficiencies across its procurement department.

Example of 4 KPIs that we can track within the platform: supplier engagement, time to respond, status of request, and response amount for suppliers. This image shows no actual confidential information and is for illustrative purposes only.

At Axya, we take immense pride in having Avior as a partner and are always thrilled to collaborate with forward-thinking companies with innovation at heart. With Axya’s RFQ solutions, Avior’s procurement processes are poised to reach new heights of optimization, and we’re honoured to help the team navigate the often complex world of sourcing so they can continue to serve customers with unparalleled agility and precision.