Case Study

Eagle Hydraulic : Keeping a Strong Supply Chain in Time of Uncertainty

Jul 14, 2022

Learn more about how Eagle Hydraulic has successfully met its urgent manufacturing needs using the Axya Strategic Sourcing module.

From trucks moving resources cross-country to snow plows helping to keep us moving in even the most unpredictable of circumstances, it’s clear that Canadians depend on a variety of machines to power and protect our everyday lives. With millions relying on their capabilities, reliability has become more crucial than ever when it comes to designing or maintaining machines across varying industries.

Luckily, reliability is no foreign concept to Canadian manufacturers like Eagle Hydraulic-- one of the country’s top manufacturers of engineered and standard hydraulic cylinders. The company operates out of its 55 000 square foot office and repair facility in Mirabel, QC and serves a network of customers across North America in industries ranging from medicine to construction.

Founded in 2003, the international success and client base garnered by Eagle Hydraulic in a mere two decades is a testament to the team’s wealth of manufacturing knowledge and a continual dedication to balancing innovation, quality work and a strong network of partners.

The Hidden Power of Hydraulic

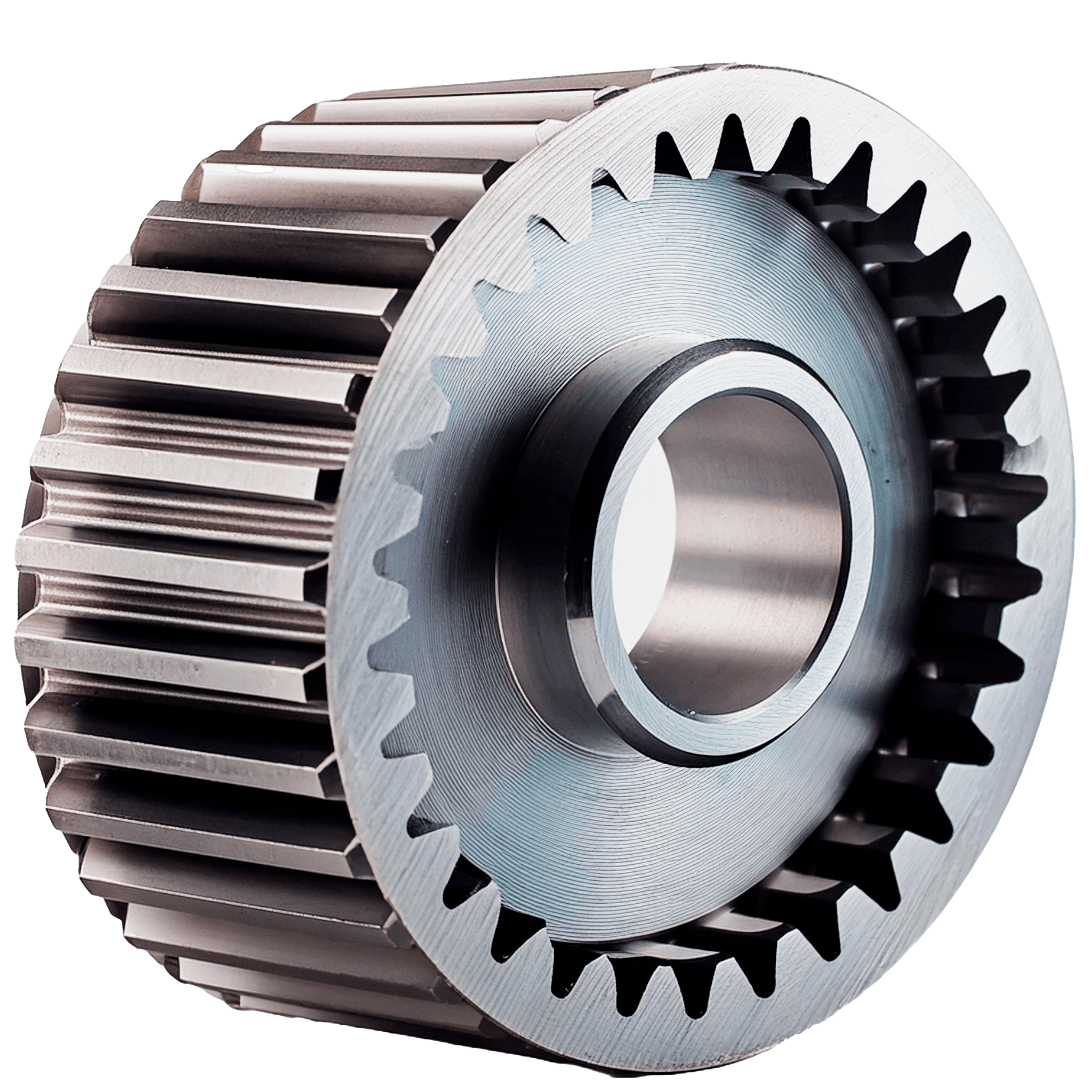

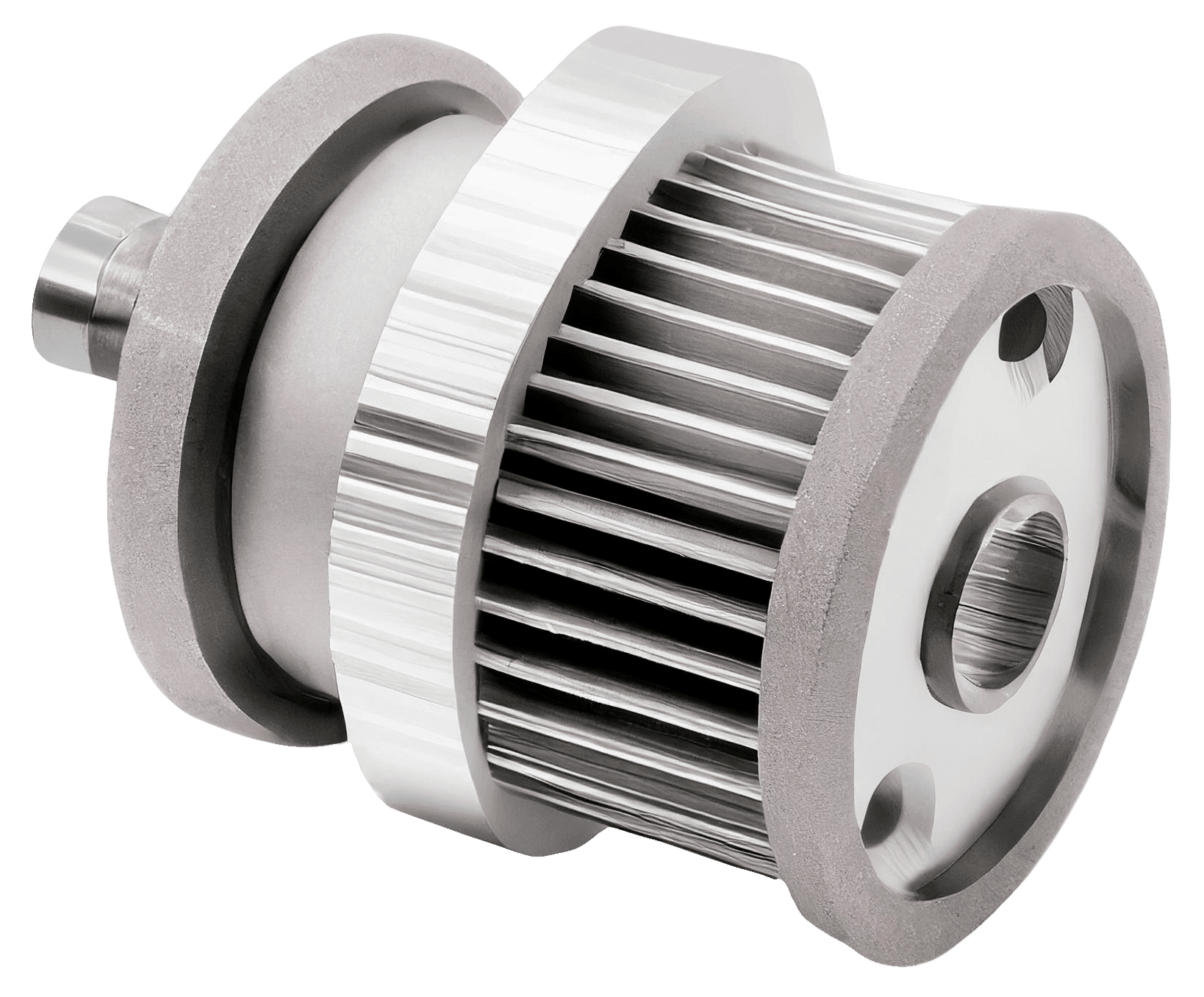

Though hydraulic cylinders like those manufactured by Eagle Hydraulic can’t often be seen from machines’ exteriors, their power is not to be underestimated. With features such as integrated valving, regenerative circuits and custom-designed sealing solutions, the company's cylinders are capable of generating large amounts of force for processes that fuel the supply chains we rely on every day.

The company has recently expanded their offerings to hydraulic power units and components in an effort to provide customers with a one-stop shop for their industry-standard hydraulic needs. One of their latest innovations, the Novapeak, is a supercapacitor which offers a more sustainable, easier to maintain and more reliable power source than a traditional battery.

On top of their innovative products, the company also holds a series of quality certifications -- ISO 9001 and 16979, to name a few --exemplifying a commitment to consistently meeting and setting industry standards. With a product range that grows with the changing industry, Eagle Hydraulic has managed to create a reputation as an industry leader capable of adapting and producing high-quality results for even the most advanced and multifaceted of hydraulic design projects.

Going Global

Despite being headquartered in a town with a population of just over 60 000, Eagle Hydraulic has established an international network of suppliers, distributors and customers all eager to be a part of their powerful approach to machinery. The team currently partners with distributors across Canada and the northern United States in order to provide personalized, regional support to prospective clients. The team also owns and operates two production facilities in China which assist with the production of several custom components-- a move that enabled the company to greatly increase international sales volume.

Despite their global presence, the team continues to keep its Canadian client base at heart. Eagle Hydraulic additionally operates several offices across the country to ensure Canadian companies are able to easily access new products and stay in close communication for guidance or assistance.

From Urgency to Opportunity

With product sales and custom requests consistently rising, Eagle Hydraulic knew it was crucial to take a closer look at the Canadian supplier market and secure robust alternatives in case a piece of their global supply chains fell through. When a part arriving from overseas was set to be delayed for weeks, the team was prepared to act fast and ensure their customer would still receive their final product on time.

Eagle Hydraulic uploaded an RFQ for the same custom part on Axya. Knowing that time was of the essence and that individually vetting suppliers would be a lengthy process, they were eager to access multiple local suppliers with just one RFQ and a few clicks.

Within just two and a half hours, Eagle Hydraulic received their first quote from a local, Quebec-based supplier who had met their specific production criteria. The team awarded the new supplier the contract on the spot and instantly began communicating further regarding their urgent need. Less than a week later, the custom part had reached Eagle Hydraulic’s door-- fast enough to completely mitigate the time they would have lost waiting for their delayed parts.

"We had urgent needs. Axya enabled us to receive quotes very rapidly and close a contract in less than two and a half hours," says Martin Leduc, a foreman at Eagle Hydraulic. "This is exactly what we needed.”

Leaning Into Local Networks

The company has since added Axya to their procurement strategy-- gaining the ability to access local solutions that complement their existing global production networks. Through Axya, the team is able to access the platform’s supplier directory and find the best partners for each custom project based on shop size, turnaround time, machining capabilities, quality certifications and more.

Eagle Hydraulic’s website highlights their commitment to ‘innovation, quality, respect, commitment, loyalty and teamwork’-- a commitment evident in the company’s willingness to go the distance and adapt. Axya is on board to help them stay true to such values in an ever-changing global manufacturing landscape-- all while ensuring that their customers receive the best products possible in record time.