Case Study

A220 Programme in Mirabel : Using Data to Optimize Procurement Processes

Dec 23, 2023

Manufacturing aircraft is no easy task. Requiring thousands of custom-manufactured components, input from various teams and rigorous testing standards, the processes for crafting such complex machines rely on efficiency, expertise and clear communication.Since 2018, Airbus has performed such production processes out of their A220 production site in Mirabel, Quebec. The site is responsible for many tasks ranging from engineering to customer support and serves as the main final assembly line for the company’s A220 aircraft.Driving Operational EfficiencyWhen producing machines capable of withstanding the most tumultuous of atmospheres and speeds, there's no question that consistent improvement and adherence to new standards are a priority. To tailor each aircraft to the needs of their clients and to maintain the highest quality standards on each component, Airbus’ A220 Programme employs strategic procurement teams to source parts through a very sophisticated supply chain. A key function of such teams is to make sure all outsourced components are assigned to the optimal supplier and that the costs and logistics of those parts respect an overarching budget and schedule.

Airbus Canada Site in Mirabel

Manufacturing aircraft is no easy task. Requiring thousands of custom-manufactured components, input from various teams and rigorous testing standards, the processes for crafting such complex machines rely on efficiency, expertise and clear communication.

Since 2018, Airbus has performed such production processes out of their A220 production site in Mirabel, Quebec. The site is responsible for many tasks ranging from engineering to customer support and serves as the main final assembly line for the company’s A220 aircraft.

Driving Operational Efficiency

When producing machines capable of withstanding the most tumultuous of atmospheres and speeds, there's no question that consistent improvement and adherence to new standards are a priority. To tailor each aircraft to the needs of their clients and to maintain the highest quality standards on each component, Airbus’ A220 Programme employs strategic procurement teams to source parts through a very sophisticated supply chain. A key function of such teams is to make sure all outsourced components are assigned to the optimal supplier and that the costs and logistics of those parts respect an overarching budget and schedule.

Airbus Canada Site in Mirabel

With this process in place, a complex and dynamic network of suppliers, and the context of a rapidly evolving manufacturing industry, the site team knew that a procurement management tool was something they needed: a solution that would standardize and automate sending out, reviewing and communicating details with all suitable suppliers of their supply chain.

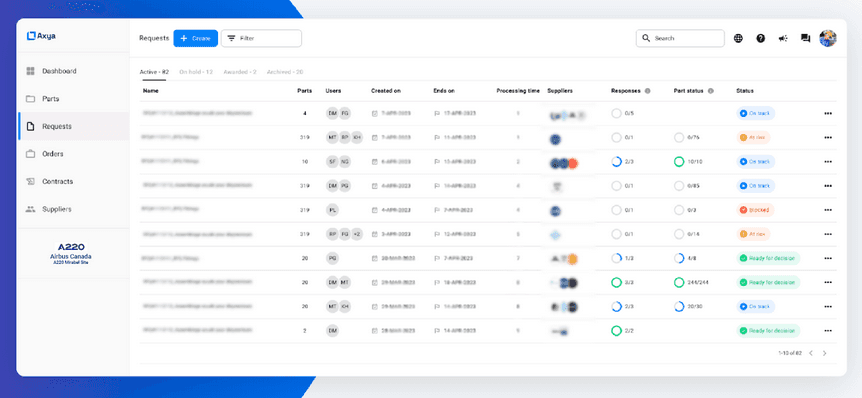

Airbus Canada’s team decided to partner with Axya, a source-to-pay solution designed with the intricacies of manufacturing supply chains in mind. Finding alignment with Axya's capabilities, the Airbus team onboarded key suppliers and began digitizing their request for quotation (RFQ) process. By going through an iterative and collaborative process on the functionalities of the product, Axya’s solution was able to standardize and automate most of the non-value-added tasks of an RFQ process:

⦿ the package transmissions to suppliers

⦿ the follow-ups required to get quotes on time

⦿ the compilation of numerous data for comprehensive quote comparisons

⦿ and the synchronization of data with other internal systems.

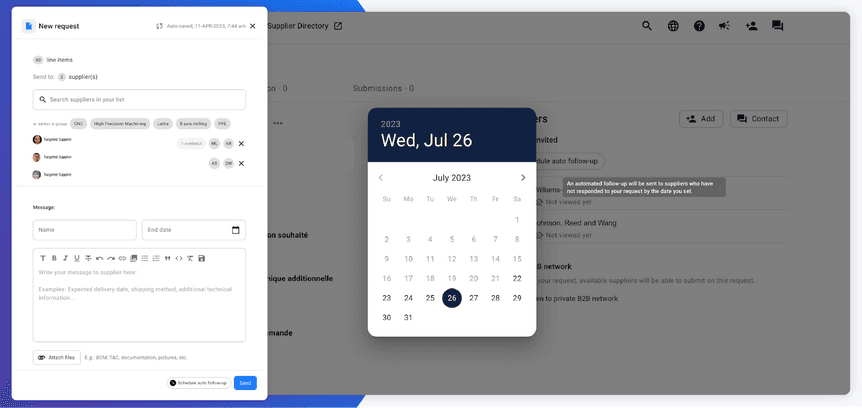

Strategic Sourcing Module, allowing procurement professional to follow their procurement activity

This image represents fake blurred data and aims to be used as an illustration only. It doesn’t show any real confidential information about any company.

Digitizing a process that was previously done by emails allowed to cut the time to manage RFQs by more than 90%, leaving the procurement team with ample opportunity to innovate further and develop stronger relationships with their suppliers.

Leveraging key data

While keeping track of numerous RFQs, orders, and communication streams, companies with multidimensional supply chains can often find it challenging to prioritize process improvement, all while keeping up with production demands.

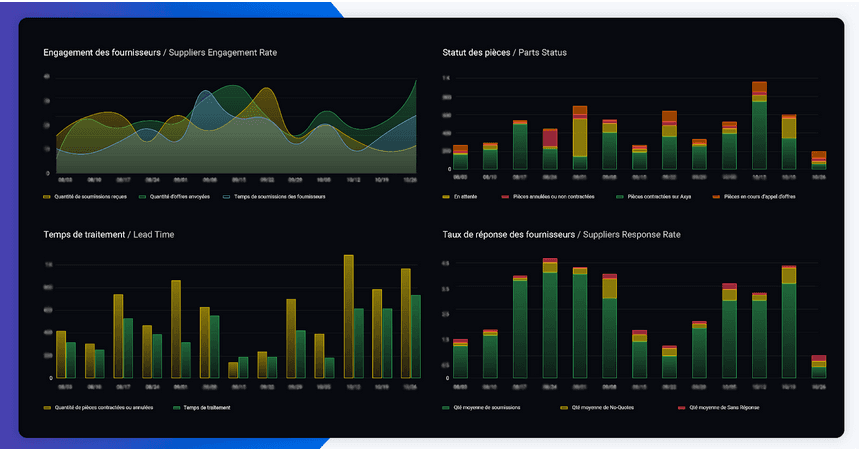

For the Airbus team, the Axya platform not only provided a means for RFQ organization and efficiency but also a means to better monitor their supply chain data as a whole and target improvement for future procurement processes.

The team highlights Axya's ability to provide quantitative KPIs on procurement activities, and supplier performance and putting concrete metrics on what had previously been gauged using perception.

Example of 4 KPIs that we can track within the platform: supplier engagement, time to respond, status of request, and response amount for suppliers.

This image represents fake data and aims to be used as an illustration only. It doesn’t show any real confidential information about any company.

Data such as the volume of requests sent allows a team to better prepare their bandwidth for seasonality and peak periods. Data on the type of parts sent in requests - i.e., type of material, certifications required, manufacturing processes, and dimensions - allow a procurement team to strategically review the type of sourcing that has the best and lowest performances to know what to tackle to improve their bottom line.

Finally, visibility on each of their suppliers’ performance allows them to be proactive in assessing any of their 100+ suppliers experiencing difficulties and to be supported by quantitative insights, helping their strategic discussions with their partners. With such data, the team has since been able to better prioritize long-term improvement objectives and improve their supplier relationships.

Keeping it simple

Airbus in Canada currently sources from over 700 Canadian suppliers. Moreover, the Airbus site in Mirabel employs around 3,000 and has created about 23,000 indirectly-sustained aerospace jobs in Canada, including other divisions and subsidiaries of Airbus. With all these stakeholders involved, implementing new platforms may seem like a daunting task. The team knew that a solution would have to be intuitive and easy to implement to become a routine tool for procurement.

Luckily, Axya works with Airbus' robust suite of existing systems-- ERP, email, shared folders, and spreadsheets and ensures that all essential data is clearly communicated internally. With additional platform features such as comprehensive quote comparison graphs, status updates

on all ongoing RFQs, automated reminders for suppliers to answer on time and clear call-to-actions that allow the buyers to focus their attention on the right RFQs to close, the Airbus team has managed to reduce their RFQ processing time by over 25%. A faster processing time means that parts are sourced faster, which also allows production to receive the parts earlier.

You can easily automate your follow-up during the lifetime of an RFQ with Axya

This image represents fake data and aims to be used as an illustration only. It doesn’t show any real confidential information about any company.

With Axya on its side, Airbus Canada can double down on its mission of supporting and leveraging Canada's aerospace expertise to revolutionize the global aviation industry. A company that has evidently believed in Canadian networks and companies from the site's opening five years ago. Now working with Axya-- a Canadian company headquartered just an hour from their A220 site-- Airbus Canada is able to leverage its innovative data-driven source-to-pay technology to enact their procurement vision.

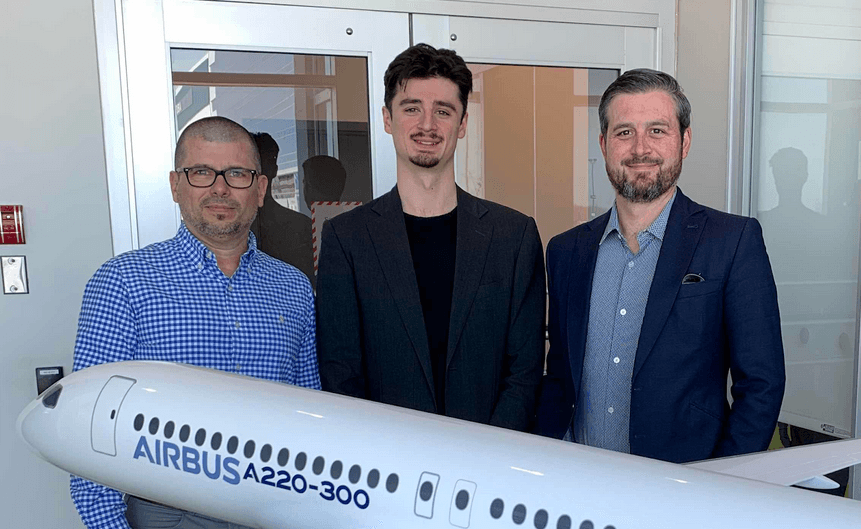

Martin Laperriere - Procurement & Strategic Sourcing Specialist at Airbus with Axya’s CEO and CRO

Axya is on board to bring efficiency and innovation to Airbus Canada’s mission each step of the way.